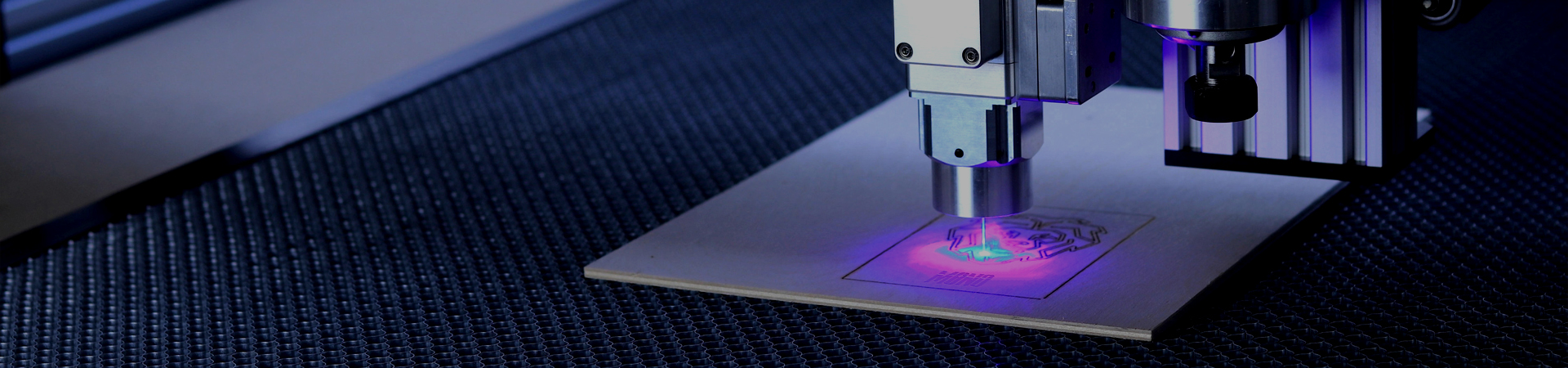

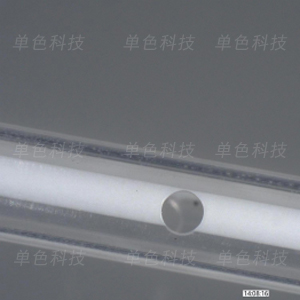

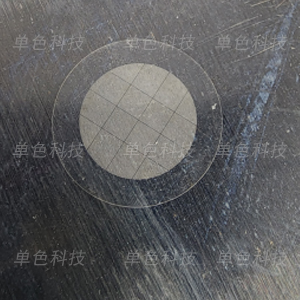

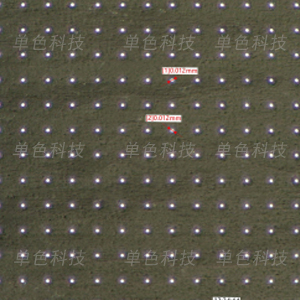

Mainly for the ultra-fine cold machining of curved surfaces, complex profile parts, can achieve high temperature alloys, metals, non-metals, especially composite materials surface micro-structure processing, such as through holes, blind holes, shaped holes, micro-cavities, cavities, shaped grooves, the equipment is suitable for all kinds of high-quality hole making.

It is applied in aerospace, biomedical, semiconductor, consumer electronics, etc. It is suitable for microfine precision microporous machining of metal, non-metal, aluminium foil, stainless steel foil, nickel alloy foil, polymer materials and other materials.