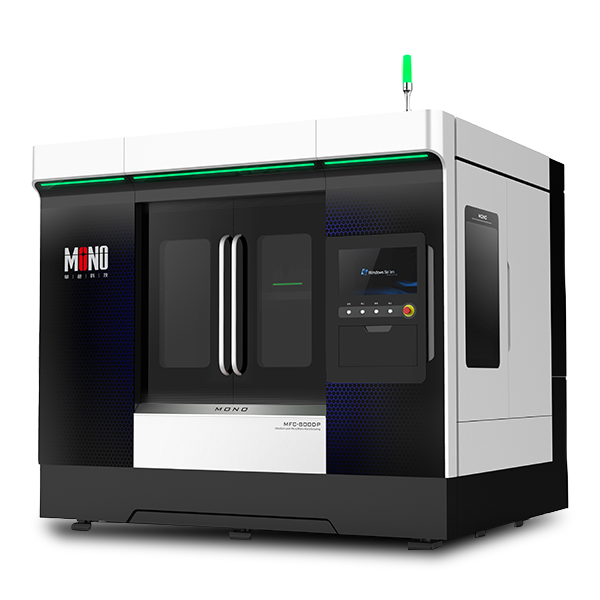

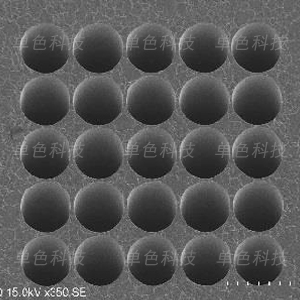

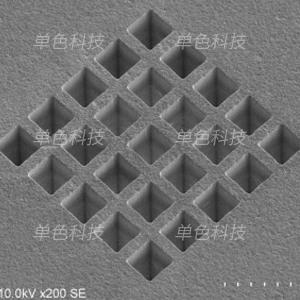

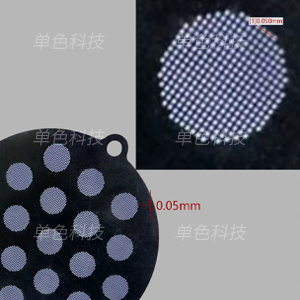

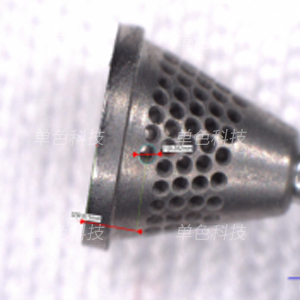

Equipped with high-quality industrial femtosecond laser with good beam quality and tiny power fluctuation, together with high-precision multi-axis control system, it can realise controlled taper fine machining of micro round holes, square holes, shaped holes, micro-cavities, cavities and other structures on all kinds of metal, non-metal, high-temperature alloys, composite materials and other materials.

Applied in aerospace, biomedical, semiconductor, consumer electronics and other fields, it is suitable for high-precision micro-hole moulding processing of key parts of the industry, such as aero-engine turbine blade air film holes, automobile fuel injector nozzles, and medical filter mesh micro-holes.