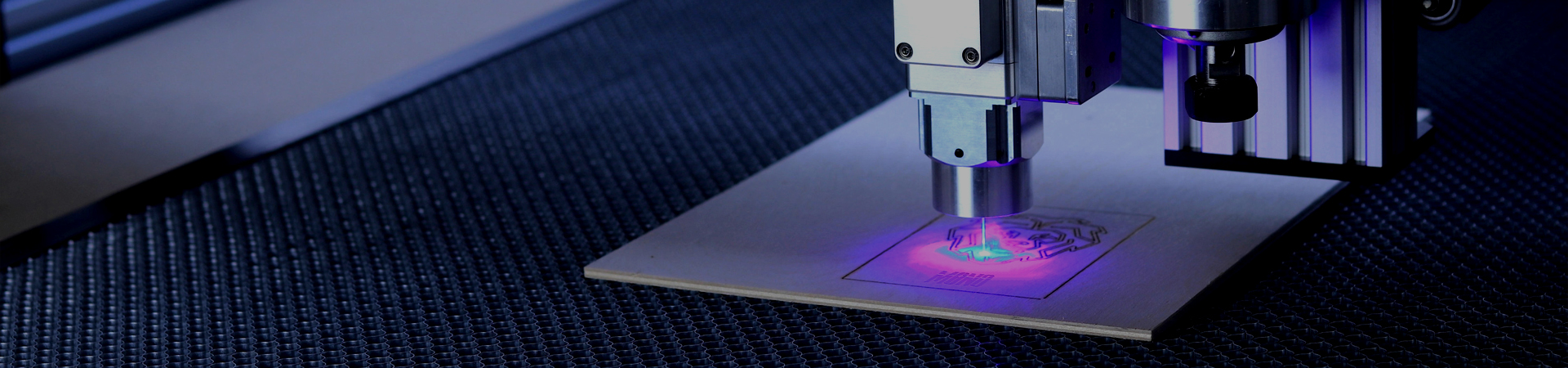

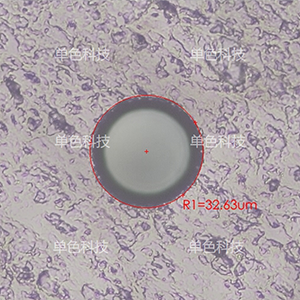

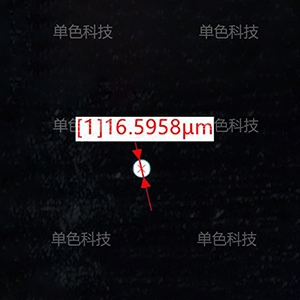

Designed for micro-hole, medium-hole and large-hole drawing mould aperture processing, it adopts high single pulse energy laser, CCD same optical path monitor, precision four-axis motion table and self-developed software control system, automatically completes the small hole forming of the workpiece, and through the programming of the hole pattern, it can punch multi-layer flared holes and tapered holes to achieve the mirror-grade finish, ultra-high consistency and higher sub-micron roundness tolerances.

It is suitable for high roundness micro-hole processing of gemstones, super-hard materials, high-temperature alloy materials and other materials.