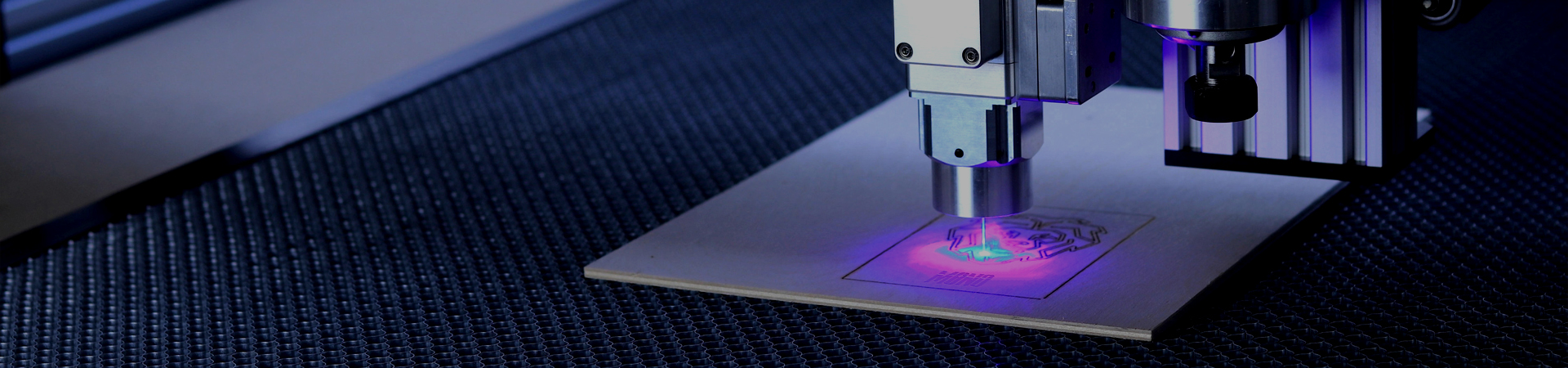

Mainly for ultra-fine cold process etching of curved surfaces and complex shaped parts.

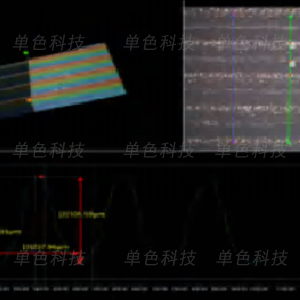

Applied in aerospace, biomedical, semiconductor, consumer electronics and other fields. Suitable for ITO, FTO, zinc oxide, zirconium oxide, titanium oxide, nickel oxide NiOx, gold, silver, carbon powder and other conductive metals, oxide materials laser etching, can achieve high temperature alloys, metals, non-metals, especially composite materials surface microstructural machining, but also for the ultra-fine linewidth laser etching, scribing, groove for glass, silicon, zirconia ceramics and other materials.