Valve sleeve is a key component in the valve, used to control the opening and closing of the fluid and throttling effect, usually used in chemical, oil and gas, electric power, water treatment and other industries.

As one of the core components of the valve, the valve sleeve is driven by compressed air or hydraulic pressure to realize precise control of the fluid. Due to its direct contact with the fluid, the design needs to take into account the durability and the ability to control the fluid. In chemical plants, angle valves (a specific type of valve) are widely used in parts of pipelines with 90-degree bends, as well as in places where installations are tighter and installed in smaller locations. This design saves space and effectively changes the direction of the material. In the power industry, valves are also widely used, such as power plants using fossil fuels and high-speed turbines to generate electricity, there is a need to use a large number of valves for fluid control.

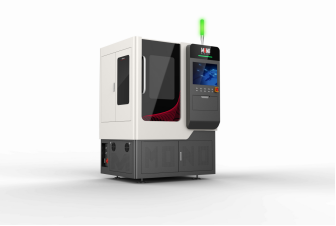

Femtosecond laser equipment can perform high-precision, low-heat-effect processing on valve bushings, including microvia drilling, surface microstructure processing, fine cutting and engraving.

Femtosecond laser technology is characterized by high energy density and a small heat-affected zone, making it excellent for processing precision parts such as valve bushings. With its ultra-short pulses and high peak power, femtosecond lasers are able to accurately create tiny structures on the surface or inside of valve bushings, thereby improving their performance.

Femtosecond laser equipment used in valve sleeve manufacturing has demonstrated extremely high precision and very low thermal impact. Specifically, this technology is capable of performing several advanced machining tasks:

1. Micro-perforation: Femtosecond laser equipment can accurately punch micro-perforations in the sealing surfaces of valve bushings. These tiny holes improve the dynamic characteristics of the fluid as it passes through the valve, reducing turbulence and wear, thereby increasing the overall efficiency and extending the life of the valve. Due to the ultra-short pulse duration of the femtosecond laser, the heat-affected area around these holes is extremely small, avoiding material deformation or damage that may be caused by traditional processing methods.

2. Surface Microstructure Processing: Using femtosecond laser technology, it is possible to create microstructures on the surface of the valve sleeve that help to optimize the performance of the valve. For example, by creating specific textures or bump patterns on the contact surfaces, it is possible to increase their resistance to wear and reduce the resistance of liquids or gases.

3. Fine Cutting: Femtosecond laser equipment is capable of extremely fine cutting operations, which is especially important for complex or difficult to machine materials. In valve sleeve manufacturing, this can be used to create complex internal passages or external shapes without leaving burrs or compromising the integrity of the material.

Femtosecond laser equipment offers a non-contact, highly accurate and efficient solution in the production and maintenance of valve bushings. As technology continues to advance and applications expand, we can expect femtosecond lasers to play a key role in many more industries in the future, especially in processes that require ultra-high precision and low thermal impact.