Tungsten, due to its unique physical and chemical properties, plays an indispensable role in many high-end fields. However, the difficulty of its processing has always been one of the challenges faced by the industry. The advent of femtosecond lasers has revolutionized tungsten sheet processing, demonstrating many significant advantages.

Femtosecond lasers are a laser technology with ultra-short pulse widths and extremely high peak powers. With pulse widths on the order of femtoseconds (10-¹⁵ seconds), when focused on the surface of a tungsten wafer, the energy can be highly concentrated on a very small area in a very short time. This unique processing method makes femtosecond lasers stand out in tungsten wafer processing.

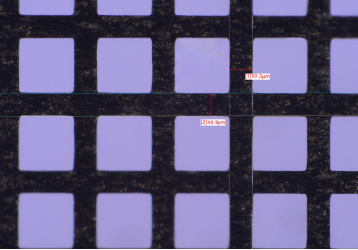

First of all, the femtosecond laser realizes high-precision processing. It is able to create microstructures on tungsten sheets with extremely precise dimensions, such as microholes with a diameter of only a few micrometers, which are regularly shaped and extremely round. In the field of electronics, when manufacturing tungsten electrodes for microelectronic devices, the high precision processing capability of the femtosecond laser ensures that the dimensions and shape of the electrodes are perfectly matched to the design requirements, thus greatly improving the performance and reliability of the electronic devices. For complex patterns and contours, femtosecond lasers also perform well, capable of engraving fine textures and patterns on tungsten sheets, such as diffraction gratings on the surfaces of optical components, etc. Their processing precision far exceeds that of traditional processing methods, making it possible for tungsten sheets to be used in the optical field.

For example, the processing of gratings with a rib width of 50 μm without carbonization, burr or thermal influence, and with a roughness of Ra < 0.4, plays a key role in the field of optical communications. Carbon-free and heat-free grating ensures that the optical properties of the grating are not impaired, and that it can accurately modulate and spectrally split light, improving the quality and efficiency of optical signal transmission. The burr-free smooth surface reduces light scattering and loss, further enhancing the performance of the optical system.

Femtosecond laser processing of tungsten flakes has the advantage of no or very small heat affected zone. The high melting point and high hardness of tungsten make it inevitable for conventional processing methods to produce a large heat-affected zone during processing, which can lead to changes in material properties, such as reduced hardness, internal stress concentration and other problems. In femtosecond laser processing, due to its ultra-short pulse characteristics, the heat conduction time is extremely short, the heat is almost too late to diffuse into the surrounding material, so there is almost no heat-affected zone. This is crucial for maintaining the original properties of tungsten flakes, especially in areas such as aerospace where the material properties are highly demanded. For example, when manufacturing high-temperature components for the aerospace industry, the use of femtosecond laser processing of tungsten wafers ensures that the components will maintain their performance and stability even in high-temperature environments. Even if there is a very small heat-affected zone, its extent can be precisely controlled within a few microns by means of optimizing the laser parameters, which further guarantees the quality and performance stability of tungsten flakes after processing. The surface quality of tungsten sheet after femtosecond laser processing is good. The processed surface is smooth and even, with low roughness and no obvious defects such as scratches, cracks and recast layers.

It is worth mentioning that Monochrome Technology has unique advantages in the field of femtosecond laser tungsten sheet processing. With advanced femtosecond laser processing equipment and professional technical team, Monochrome Technology is able to provide customized solutions for different tungsten sheet processing needs. It is in the leading position in the industry in terms of laser parameter optimization and processing process innovation. For example, through the self-developed intelligent control system, Monochrome Technology is able to accurately regulate the pulse energy, pulse width, repetition frequency and other parameters of femtosecond laser, realizing precise control of tungsten wafer processing, and further improving the processing accuracy and quality. Meanwhile, Monochrome focuses on the optimization of the processing environment in the process, adopting advanced dust absorption and heat dissipation devices, effectively reducing the dust pollution and heat accumulation in the process, and improving the stability and reliability of the processing.