1, Introduction

Femtosecond (Femtosecond,fs), also known as millimicroseconds, is 10^-15 s. Femtosecond lasers operate in the form of pulses with a duration of only 10-100 fs in general, which is the shortest pulse that can be obtained under the current state of the art. Because of this, once the femtosecond laser was born, it has been widely used in microscopic processes in the fields of physics, biology and chemistry, thus discovering many new ultrafast phenomena.

2、Features

Extremely short pulse width: Pulse width refers to the duration of time when the laser power is maintained at a certain value. The duration of femtosecond laser is only a few femtoseconds, which is the shortest pulse technology means that can be obtained under the current laboratory conditions, and it is thousands of times shorter than the shortest pulse obtained by using electronic methods.

The peak power of the pulse is extremely high: The peak power of a femtosecond laser is the instantaneous power for the duration of the pulse. Since the duration is extremely short, the instantaneous power can be up to a million billion watts even in the case of very small energy, which is a hundred times more than the current total power of electricity generation in the whole world, and is one of the choices of energy in the future.

Extremely wide spectral coverage: a pulse with a pulse width of tens of femtoseconds can contain up to millions of spectral components, equivalent to millions of continuous wave (CW) lasers with different centre wavelengths that maintain equal frequency intervals, a specificity of femtosecond lasers that has gained significant applications in metrology standards and precision measurements.

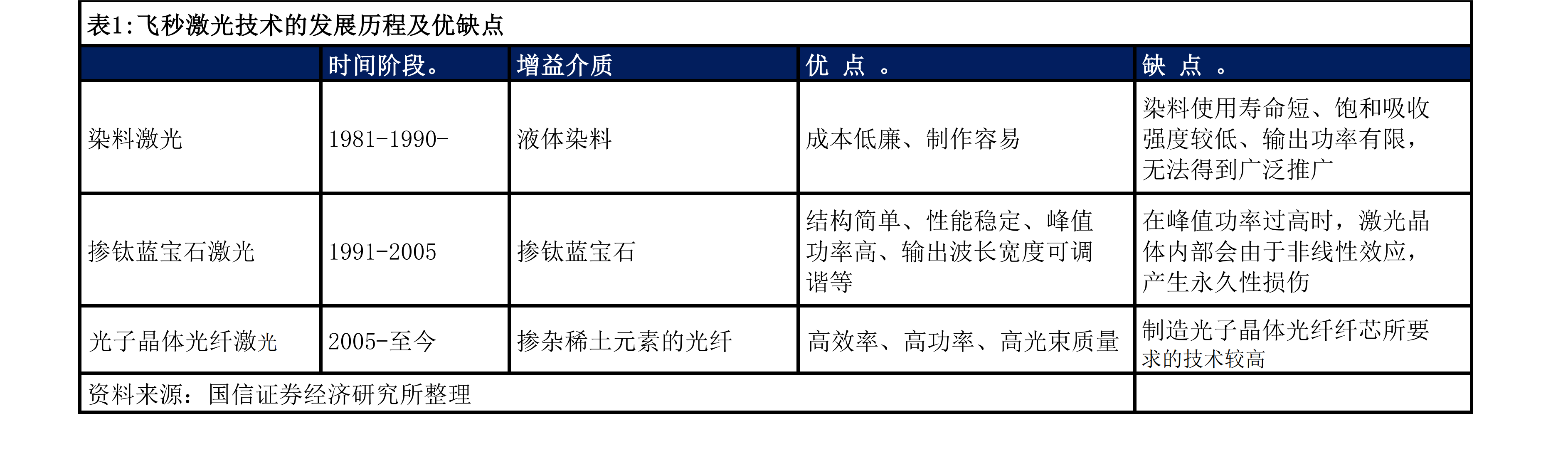

3. Development history

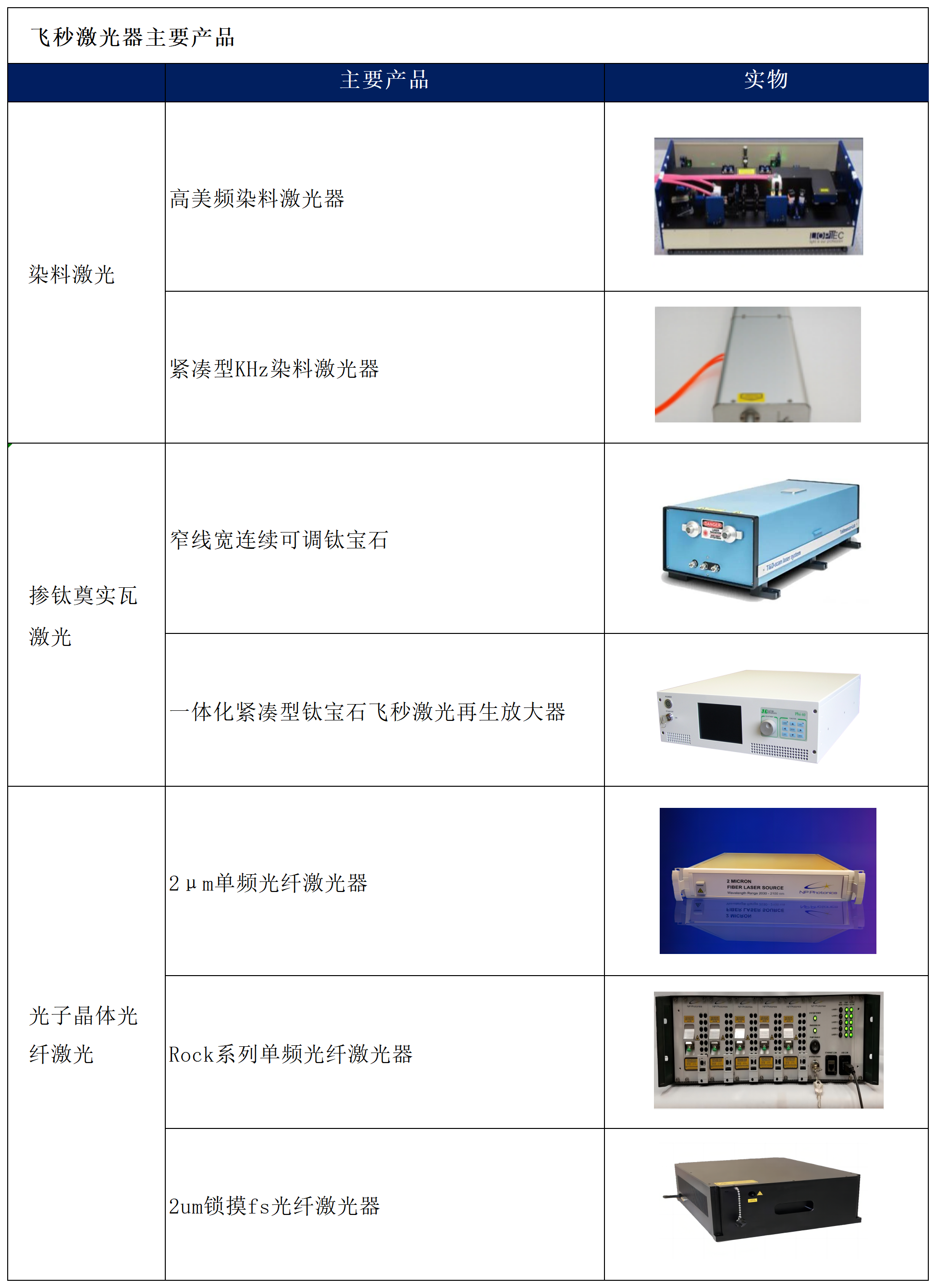

Femtosecond lasers have gone through three stages of development in their history, from the original dye laser to the sapphire laser and then to the latest photonic crystal fibre laser, a total of 40 years of development. With the development of technology, the pulse width of femtosecond laser is getting shorter and shorter, the peak power of the pulse is getting bigger and bigger, and it is gradually moving from laboratory to industrial application.

4、Application field

As the femtosecond laser has the characteristics of extremely short pulse width, extremely high peak power and extremely wide coverage of the frequency spectrum, resulting in its fine micro-processing with many excellent characteristics that traditional processes do not have. The extremely short pulse width can produce very high power in an instant, so it will not produce excess heat, thus avoiding the phenomena of material cracking, breaking, melting and so on during the process, and then get very high-quality processing effect, which is especially important for the fine micromachining of brittle materials such as glass, sapphire and so on. It is because of the excellent characteristics of the femtosecond laser, resulting in its increasingly wide application in the field of industrial production. Specifically, there are the following points:

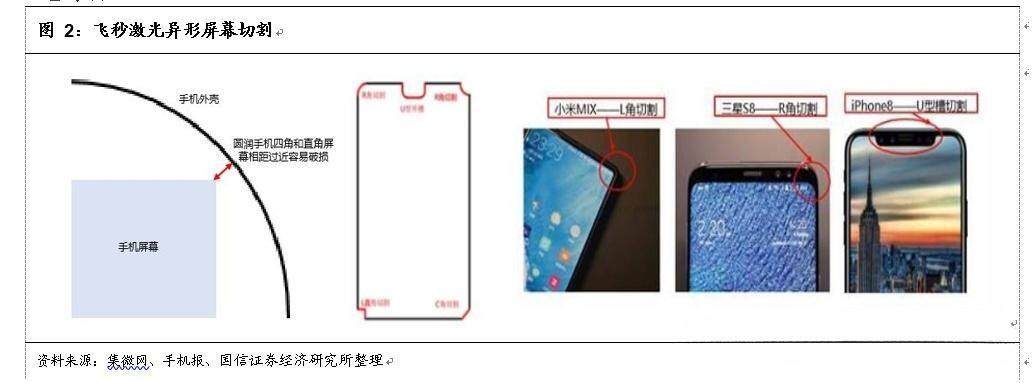

Shaped screen cutting: most of the traditional mobile phone screen with a right angle, the production of this kind of screen is relatively simple, the required level of technology is also relatively low. However, with the growing popularity of full-screen mobile phones, such as still using a right angle, easy to lead to the screen is fragile, so it is necessary to screen for the shaped cut: the current mobile phone screen is still based on the LCD screen, this kind of screen to the glass as a substrate, not only hardness, but also more fragile, is not suitable for the traditional cutting method for fine processing. With the emergence of femtosecond laser direct cutting technology, due to its use of high-power beam cutting, with high precision, good cutting effect, no damage to the material and many other advantages, thus solving the shortcomings of the traditional process.

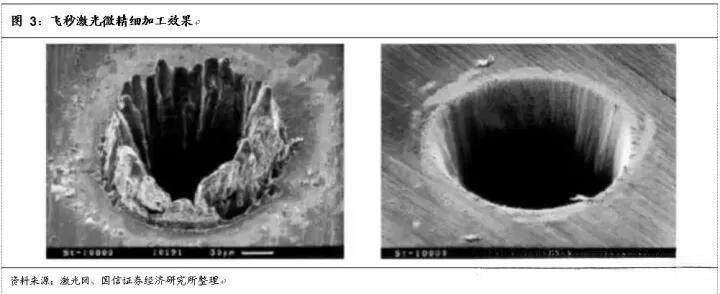

Microfine processing of brittle materials: The three main characteristics of femtosecond laser determine that it can be widely used for processing various fragile and high-performance materials, such as glass, sapphire, ceramics and so on. Since the femtosecond laser concentrates the beam into the ultrafine space, cracks in the material can be avoided during processing, and the processed aperture has a smooth inner wall, which reduces the generation of surface debris to a greater extent. In addition, the femtosecond laser can also be used for micro-processing and etching inside a variety of materials, achieving ultra-fine processing.

Myopia surgery: In the medical field, the extremely short pulse width and high power of the femtosecond laser means that no excess heat is generated during the procedure, thus greatly reducing pain and additional damage to the patient. The most mature use of femtosecond laser technology in the medical field is in the treatment of myopia. The degree of the corneal flap made by femtosecond laser is controlled within 10 microns, which is much higher than that of the traditional laminar layer, and it effectively avoids the surgical complications that are prone to arise from the use of metal knives for making corneal flaps, thus improving the safety of the surgery.

Removal of thin materials: With the continuous development of semiconductor materials, integrated circuits are increasingly miniaturised and complex, thus requiring continuous refinement of the processing technology, the limitations of the traditional manufacturing process is increasingly prominent. For example, the thickness of semiconductor wafers continues to get thinner and smaller, and the difficulty of processing them is gradually rising. Femtosecond laser technology highly concentrates the light beam with extremely short laser pulses and high peak power, thus enabling the removal of an extremely thin layer of material without affecting the underlying material, thus achieving material processing quality and precision.