In the field of modern micromachining, femtosecond laser technology has brought new solutions to the microstructure etching of epoxy resin materials. Especially when it comes to processing thousands of microstructures with specific angles and depths, femtosecond lasers offer unique advantages.

Epoxy resin is a material widely used in electronics, optics and other fields, and is favored for its good insulation, chemical stability and processability. However, etching microstructures with high precision is not an easy task. When it comes to processing microstructures with a 45° angle on epoxy materials with bump depths of up to 50 μm, traditional processing methods present a number of challenges. For example, machining is prone to generate large cutting forces, resulting in surface damage and microstructure deformation of materials; Chemical etching, on the other hand, is difficult to control shape and depth and can adversely affect the chemical properties of the material.

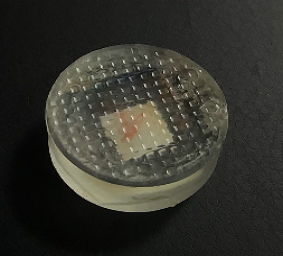

Epoxy material (sample image)

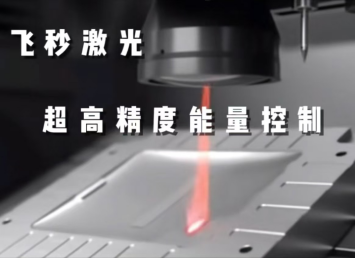

The principle of femtosecond laser processing is based on its extremely short pulse duration. Femtosecond pulses concentrate high energy in tiny areas of the material in a very short period of time, rapidly ionizing the material and forming a plasma that can be removed from the material. For etching of 45° angled slope-like microstructures on epoxy materials, femtosecond lasers can be achieved by controlling the path and energy of the laser beam. Through computer programming, the laser beam can move across the surface of the material at a preset angle of 45°, progressively etching the desired ramp shape.

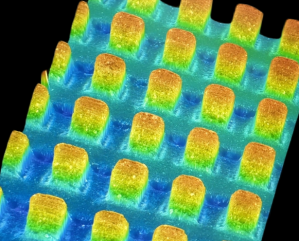

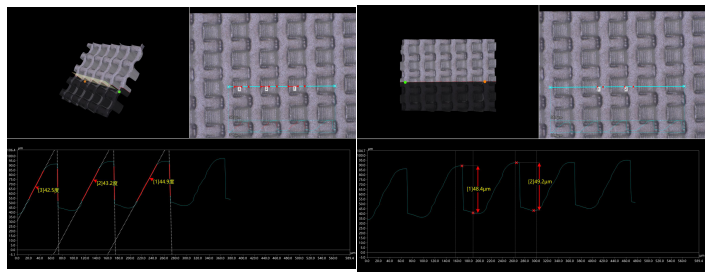

45° slope micro-convex etching (confocal microscopy imaging)

In the process of ensuring a bump depth of 50 μm, the energy control of the femtosecond laser is key. The right amount of energy ensures that the right amount of material is removed for each pulse to reach the exact predetermined depth. If the energy is too high, it may cause excessive removal of the material and destroy the shape of the microstructure; If the energy is too low, the processing efficiency will be low, and even the required depth will not be reached. This requires fine tuning and optimization of parameters such as pulse energy, frequency, and scanning speed of the laser.

A significant advantage of femtosecond laser processing is the ability to avoid problems such as edging, carbonization, and microstructure collapse. Due to the extremely short femtosecond laser pulses, the heat-affected area generated during material processing is extremely small. In conventional processing methods, the edges of the material can be melted and carbonized by prolonged thermal action, but this can be greatly avoided when the epoxy microstructure is processed by femtosecond laser. For the problem of microstructure collapse angle, the high-precision energy control and path planning of femtosecond laser ensure the uniformity of material removal, so that the microstructure can maintain a stable shape during the etching process, and will not cause collapse due to local over-processing.

The action time is short, and the heat-affected area is small

This thousands of specific microstructures, processed on epoxy resin materials, have important applications in a variety of fields. In the field of optics, it can be used to fabricate microlens arrays to change the propagation path of light through a 45° angle slope-like microstructure to improve the performance of optical systems. In the field of electronic packaging, these microstructures can increase the contact area between epoxy resins and other components, improving the reliability and heat dissipation performance of the package.

Measurement data

In short, the application of femtosecond laser in the microstructure etching of epoxy resin materials provides high-precision and high-quality processing methods for the development of related industries, and promotes the progress of micro-nano manufacturing technology. Monochrome technology plays a key role in this process, and its advanced femtosecond laser equipment and professional technical team ensure the accuracy and stability of the entire processing process. Through continuous R&D investment, Monochrome Technology continuously optimizes the femtosecond laser processing process, provides a more reliable and efficient solution for microstructure etching, and further expands the application prospects of this technology in various fields.

Five-axis femtosecond laser precision etching equipment