For extreme precision machining in a wide range of industries including medical devices, aerospace, semiconductors, etc.

——

36 Krypton was informed that the extreme ultra-precision laser equipment company Shenzhen monochrome technology limited (hereinafter referred to as "monochrome technology") announced the completion of tens of millions of yuan of A round of financing, this round of financing by the knowledge of the city of venture capital, qinquan capital investment. According to reports, the funds will be mainly used to increase R & D investment in the field of extreme intellectual microfabrication, as well as to cope with the growth of orders to increase the operating capital.

Monochrome Technology was founded in 2020, focusing on extreme intellectual ultra-fast laser microfabrication application equipment in the field of advanced manufacturing. For industrial processing in the extreme precision processing scenarios to provide solutions, business direction for nanoscale hole making, submicron etching, ultra-fine cutting, able to solve the needs of medical devices, aerospace, semiconductors and other industries extreme precision processing.

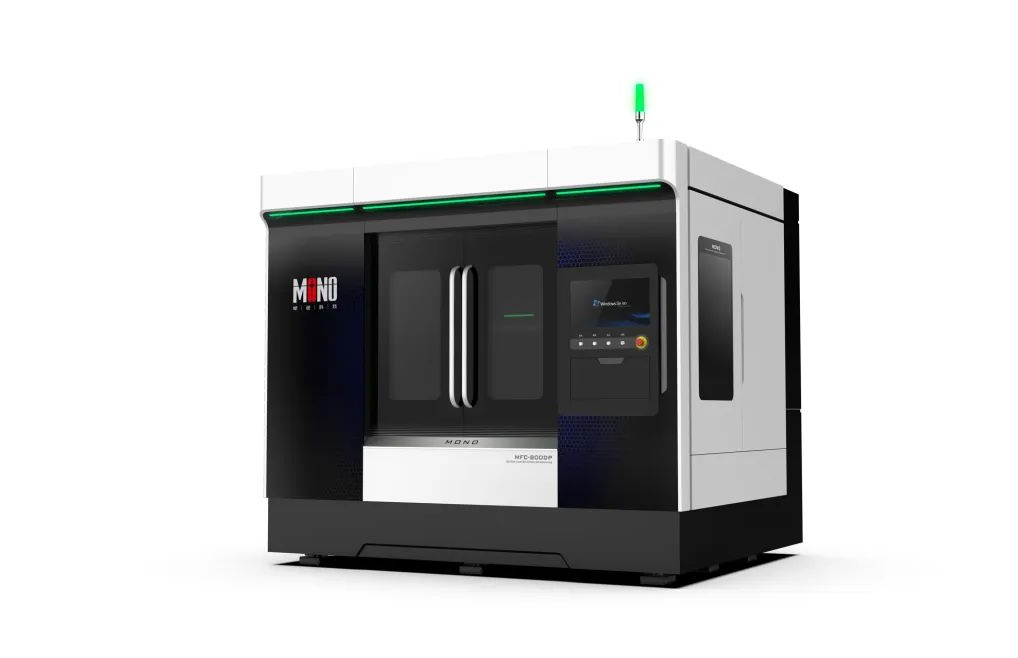

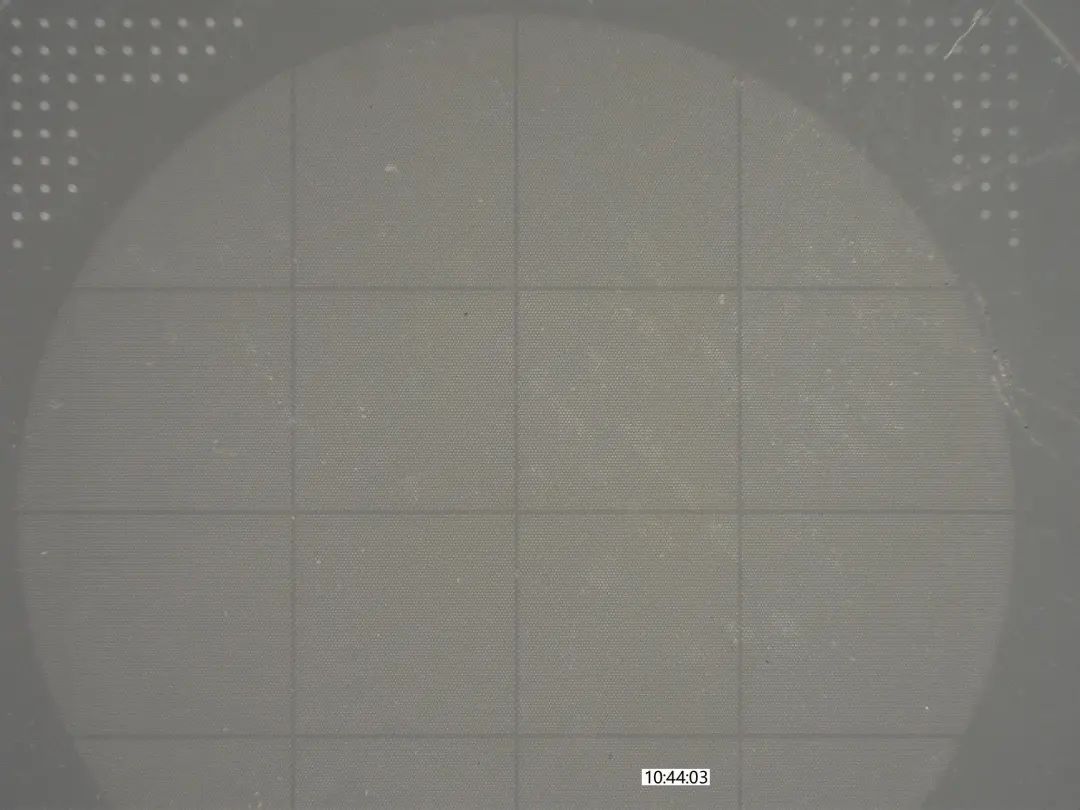

Extreme ultra-precision laser equipment from Monochrome Technology Earlier this year, 36 Krypton has reported that monochrome technology with large area three-dimensional free-form surface laser engraving machine won the annual special procurement plan of the key laboratories, the successful completion of the A round of financing also indicates that the domestic head of the investment institutions of its research and development in the field of advanced equipment and the recognition of industrialisation capabilities. "The enhancement of extreme microfine basic processing capability will be conducive to promoting the overall level of precision manufacturing industry and significantly improve the performance of products in downstream application industries." Qiao Lei, founder and CEO of Monochrome Technology, told 36 Krypton: "Monochrome Technology has broken through the bottleneck of the minimum processing resolution of the same kind of equipment in China through the advanced optical field regulation technology, high-precision platform system, motion control system, and software control system, and solved the problems of low precision and slow processing efficiency that plague large-format micro- and nano-optical processing at home and abroad. " Monochrome technology adhere to independent research and development, technology to pull the development of the company, in the optical research and development, new materials and new process research, software algorithms and other areas of sustained investment, through the various technology modules with the realization of more extreme requirements, the company has applied for various types of patents since its inception more than 20. In practical applications, laser processing process has a variety of extreme requirements, including extreme processing scale and precision requirements, extreme shape requirements, the quality of the surface integrity as well as extremely difficult to process the material efficient processing issues. Monochrome Technology independently developed beam shaping system, beam control to the wall protection mechanism, with its self-developed automatic control system and supporting extreme microfabrication software system, systematically solves the above problems, and can achieve nano-scale hole making. 11 micron diameter group of holes (number of holes: 120,000) magnified 30 times

11 micron diameter group of holes (number of holes: 120,000) magnified 500 times

Ultrafast lasers have increasingly broad application prospects in precision medicine, aerospace, semiconductors, and refined consumer electronics by virtue of the three major advantages of no material selectivity, no thermal effects, and surface integrity of the material after processing. According to industry estimates, the ultra-fast laser equipment market will grow at a CAGR of 15.6% by 2026, and the market size will grow from RMB 12 billion in 2022 to nearly RMB 20.7 billion in 2026.

Monochrome Technology's core team in the field of ultra-fast laser fine processing has a wealth of experience, CEO Qiao Lei has 15 years of experience in the laser processing of intelligent equipment manufacturing industry, and 7 years of entrepreneurial experience, R & D head of Dr. Wang Yulong in the ultra-fast light field spatial and temporal regulation, metal optics, ultra-fast lasers and the role of matter have in-depth research in the field of, independent of the establishment of a complete set of perfect femtosecond pulse spatial and temporal regulation model. The research results have been published in Opto-Electronic Advances, Nanophotonics and other internationally renowned journals. Monochrome Technology has technical and product advantages in precision medicine, aerospace and other fields, and continues to provide customers with low-cost, high-performance solutions.

Qiao Lei said: Founded three years ago, monochrome technology in the aerospace and medical fields have been achieved in the domestic strong alternative to the international advanced level, and access to the recognition of a number of domestic customers, with the future continued investment in research and development, expanding the market application, the company's operating income can be maintained annual exponential growth.

This article is reprinted from 36 Krypton.