Femtosecond laser processing technology has a high application potential in the cutting and punching of molybdenum sheet, tungsten sheet, stainless steel, copper-nickel alloy and other metal sheets. The femtosecond laser has a very short pulse width and peak power, enabling it to achieve high accuracy, low heat affected zone and small thermal deformation, which is suitable for fine machining of thin sheets. The following are the main applications of femtosecond lasers in the processing of these metal sheets:

1. Cutting: femtosecond laser can be used for steel, stainless steel, molybdenum, tungsten and other metal sheet cutting. Due to their high energy density and short pulse width, femtosecond lasers are able to quickly process metal materials into the desired shape, and the cutting edge quality is high, usually without additional surface treatment.

2. Drilling: femtosecond laser can be used for the processing of microholes on metal sheets. Due to its high energy density and small heat-affected zone, femtosecond lasers can achieve tiny apertures and high-quality holes, and can avoid material deformation or damage due to heat effects.

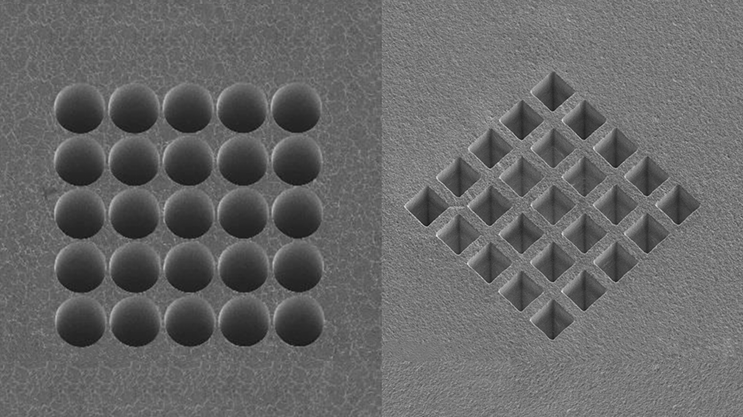

3. Etching: Femtosecond laser can also be used for surface etching of metal sheets, including patterned etching, microstructure etching, etc. By controlling the processing parameters of femtosecond laser, the fine processing of metal surface and the structure control at nanometer level can be realized.

Femtosecond lasers have many advantages in the cutting, drilling and etching of molybdenum, tungsten, stainless steel, copper-nickel alloy and other metal sheets, including:

1. High accuracy: femtosecond laser pulses are very short, usually between a few femtoseconds and several hundred femtoseconds, so very high accuracy can be achieved. This makes it possible to achieve micro-sized holes, fine structures and fine etching in metal sheets.

3. Low heat affected zone: The energy density of the femtosecond laser pulse is very high, which can quickly evaporate and remove metal materials, with almost no heat conduction to the surrounding area. Therefore, the heat affected zone formed during femtosecond laser processing is very small, and there is almost no thermal damage and deformation, which is especially suitable for fine processing of metal sheets.

4. No auxiliary materials: Auxiliary materials, such as coolant or protective gas, are usually not required during femtosecond laser processing. This simplifies the processing process and reduces costs and the need for equipment maintenance.

4. No post-treatment: Since there is almost no heat-affected zone during femtosecond laser processing, there is usually no need for post-treatment, such as cleaning edges, removing oxides or surface treatment. This saves time and costs and increases productivity.

5. Wide applicability: femtosecond laser technology has a good adaptability to various metal materials, including molybdenum sheet, tungsten sheet, stainless steel, copper-nickel alloy, etc. As a result, high quality machining can be achieved on different metal sheets to meet the needs of various applications.

Femtosecond laser has the advantages of high precision, low heat-affected zone, no auxiliary materials and no post-treatment in the cutting, drilling and etching of metal sheets, which is a very effective processing technology.