Femtosecond laser cutting and perforating equipment is being used more and more widely in various fields, and in the field of filtration membranes, the application of such equipment has also achieved remarkable results.

First, the principle of femtosecond laser technology

Femtosecond laser is a kind of ultra-short pulse laser, whose pulse width is at the level of femtosecond (1 femtosecond is equal to 10-15 seconds), and has extremely high instantaneous power and energy density. Using these characteristics of femtosecond laser, it is possible to carry out fine processing of various materials, such as cutting, punching, etching and so on. In the field of filtration membrane, femtosecond laser can realise high-precision and high-efficiency processing of filtration membranes of different materials and thicknesses.

Second, the technical advantages

Compared with traditional mechanical processing methods, femtosecond laser cutting and perforating equipment has the following advantages in filter membrane processing:

1. High precision: the pulse width of femtosecond laser is extremely short and the energy density is extremely high, which can carry out fine processing on the surface of the material and realise high-precision cutting and punching.

2. high efficiency: the processing speed of femtosecond laser is very fast, which can complete a large number of processing tasks in a short period of time and improve the production efficiency.

3. Various materials can be processed: femtosecond laser can process a variety of different materials and thickness of the filter film to meet different needs.

4. environmental protection: femtosecond laser processing does not produce harmful substances, harmless to the environment.

III. Application effect

The application effect of femtosecond laser cutting and punching equipment on filter membrane is mainly reflected in the following aspects:

1. Improvement of filtration effect: through the cutting and perforation of the filter membrane, it can make it have better filtration effect and improve the filtration precision.

2. prolonging service life: the filter membrane processed by femtosecond laser has higher strength and durability, which can prolong its service life.

3. Reducing production cost: femtosecond laser processing speed, high processing efficiency, can reduce production cost.

4. Promote technological innovation: the application of femtosecond laser technology promotes technological innovation in the field of filtration membranes and injects new vitality into the development of the filtration membrane industry.

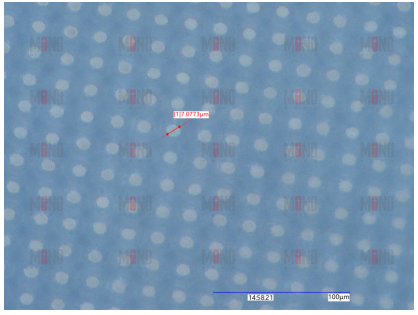

7μm femtosecond laser processing on ten thousand microporous

Fourth, the future development trend

With the continuous progress of science and technology and application needs continue to improve, femtosecond laser cutting and punching equipment in the field of filtration membrane will be more and more widely used, can be realised PI film, PET film and other types of flexible materials and thin film products precision scribing, cutting. In the future, this kind of equipment will make greater development in the following aspects:

1. Higher processing efficiency: with the continuous progress of technology, femtosecond laser processing efficiency will be further improved to further increase production capacity.

2. Higher processing accuracy: In the future, the processing accuracy of femtosecond laser will be higher, and can achieve more fine processing results. 3.

3. Wider range of processable materials: at present, the femtosecond laser can process a wide range of materials, and will further expand the range of processable materials.

4. higher degree of intelligence: with the continuous development of intelligent technology, the future of the femtosecond laser equipment will have a higher degree of intelligence, to achieve automation, intelligent processing operations.

In short, the application of femtosecond laser cutting and punching equipment in the field of filtration membrane has achieved remarkable results, the future will be in the technology, efficiency and the degree of intelligence and other aspects of greater development. The application of this technology will bring new opportunities and challenges for the development of the filtration membrane industry.