Femtosecond laser cutting equipment on the slit film has multiple advantages, the process of femtosecond laser cutting equipment on the slit film usually includes the following key steps:

I. Preparation:

Prepare the slit sheet to be processed and ensure its surface is clean.

Set up the femtosecond laser cutting equipment, including adjusting the laser power, pulse frequency, focusing parameters and so on.

Ensure the stability and safety of the processing environment and prevent external factors from interfering with the process.

Second, positioning and alignment:

Place the slit sheet on the processing table and use a microscope or other auxiliary tools to locate and align the processing area.

Ensure the accuracy and stability of the machining position in order to achieve fine machining.

Third, processing parameter setting:

According to the material characteristics of the slit piece, processing requirements and equipment specifications, set the appropriate femtosecond laser processing parameters, including laser power, pulse width, scanning speed and so on.

Adjust the processing parameters to ensure better processing effect and processing quality.

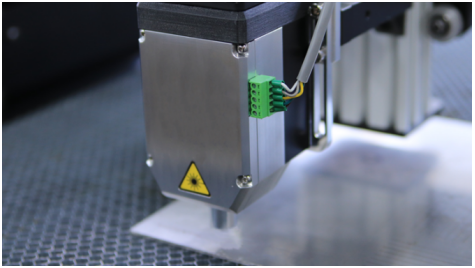

Fourth, femtosecond laser cutting:

Start the femtosecond laser and focus the laser beam on the processing area of the slit sheet.

Control the travelling path of the femtosecond laser beam to achieve the desired cutting shape and size.

By controlling the energy and time of the laser pulse, cut the slit sheet layer by layer until the desired processing task is completed.

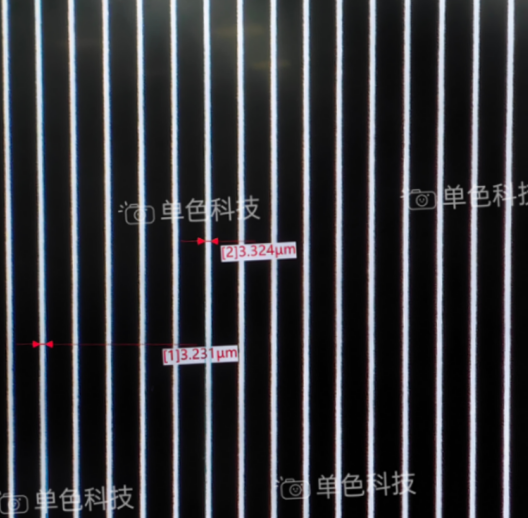

V. Quality inspection:

After completing the machining, the machining results are checked and assessed for quality.

Use a microscope or other testing equipment to check the smoothness of the processed surface, edge quality and dimensional accuracy and other parameters to ensure that the processing quality meets the requirements.

Through the above steps, the femtosecond laser cutting equipment can achieve fine processing on the slit sheet and obtain high-quality processing results. Femtosecond laser cutting equipment processing on slit sheet has multiple advantages such as high precision, non-thermal influence, no need for post-processing, material adaptability, micro-damage processing, processing flexibility and environmental protection and energy saving, which makes it an ideal micro and nano processing technology.