Light guide moulds are usually industrial moulds used to produce light guides in LED luminaires. Light guide plate is an important component in LED lamps and lanterns, its role is to evenly distribute the light in the LED light-emitting area, so that the light can be more evenly scattered and projected, to improve the lighting effect and light energy utilisation.

Light guide moulds are usually designed by mould designers and manufactured by mould makers. These moulds are usually made of high quality metal materials (such as aluminium alloy or steel) to ensure that the moulds have sufficient strength and durability. The moulds must be designed to ensure that the shape, size and surface quality of the light guide plate meet the requirements.

The process of manufacturing a light guide plate mould usually includes the following steps:

1、Mould design: The mould designer designs the structure and size of the mould according to the requirements of the light guide plate.

2, manufacturing mould parts: according to the design, manufacturing the mould required for each part, which may involve CNC machine tool processing, laser processing and other processes.

3、Assembling the mould: assembling the manufactured parts into a complete mould structure.

4, debugging the mould: debugging the assembled mould to ensure that the mould can operate normally and produce the light guide plate in line with the requirements.

5, the production of light guide plate: the use of debugging the mould for production, usually through the injection or calendering process of plastic or other materials made of light guide plate.

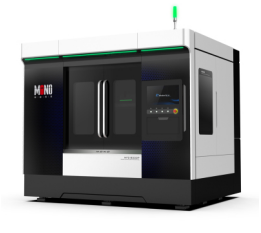

Femtosecond laser micro-nano processing equipment can play a key role in the manufacture of light guide plate moulds, especially in the parts that require high-precision processing. This kind of equipment, using femtosecond laser technology, can achieve very fine processing with the following characteristics:

1, high-precision processing: femtosecond laser micro-nano processing equipment can achieve micron or even sub-micron level accuracy, so it is very suitable for the manufacture of mould parts that require high precision.

2, micro-fine structure processing: due to the ultra-short pulse time of the femtosecond laser, it can achieve very fine cutting and processing of the material, the manufacture of micro and nano level structure and surface features.

3, no thermal impact: one of the characteristics of femtosecond laser processing is that its processing process produces very small thermal impact, can avoid thermal damage and deformation around the material, to ensure the accuracy and quality of the processed parts.

4, applicable to a wide range: femtosecond laser micro-nano processing equipment can be used to process a variety of materials, including metals, plastics, ceramics, etc., so in the manufacture of light guide plate moulds can cope with the processing needs of different materials.

In the manufacturing process of light guide plate mould, femtosecond laser microporous processing equipment can be used to manufacture the fine structure of the mould, micro-channels, micro-holes and other components to ensure that the mould has good optical properties and surface quality. At the same time, through the femtosecond laser micro-nano processing, it can also achieve the processing of some complex shapes and improve the design flexibility and production efficiency of the mould.

Femtosecond laser micro-hole forming equipment