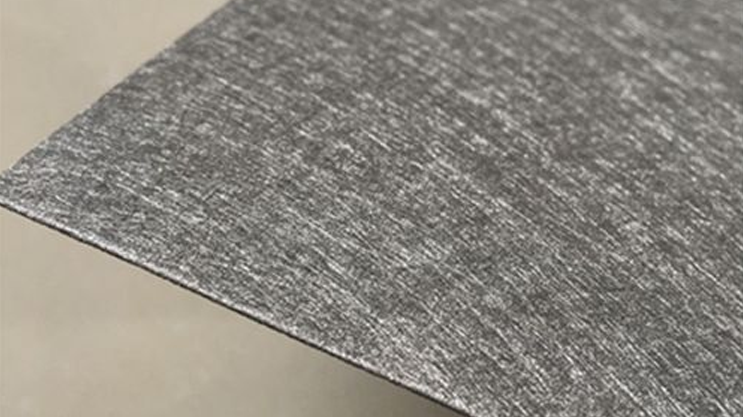

Metal fibres are fibrous objects made from metallic materials. Metallic fibres have a higher surface area density and a larger specific surface area than conventional metallic materials, and therefore offer unique advantages in a number of specific applications.

The type and properties of metal fibres depend on the metal material chosen, common metal fibres include stainless steel fibres, copper fibres, aluminium fibres and others. These metal fibres can be used alone or in combination with other materials such as polymers, ceramics, etc. to meet the requirements of specific applications.

Femtosecond laser micro-nano processing is an advanced manufacturing technology that can be used to process materials such as metals, ceramics, glass, etc., especially for fabricating micro- and nano-scale structures. Thin metal fibre sheets are complex structures that require high-precision processing techniques.

The principle of femtosecond laser micro-nanometer processing is to use the very short time characteristic of femtosecond laser pulses to focus the energy in a very small area, so that the material undergoes a very rapid change, thus realising the machining precision of micron or even nanometer level. This processing technology has the following characteristics:

High precision: Femtosecond laser processing has extremely high processing precision, capable of achieving micro and nano level processing.

Non-contact processing: laser processing is a non-contact processing technology, which can avoid contamination and damage to the material surface.

Wide applicability: Femtosecond laser processing technology is applicable to a wide range of materials, including metals, ceramics, glass, etc.

Flexibility: Processing of different shapes and sizes can be achieved by adjusting laser parameters and processing paths.

Low heat-affected zone: Due to the extremely short processing time, the heat-affected zone is very small and thermal damage to the material can be reduced or avoided.

For the processing of thin metal fibre sheets, femtosecond laser micro-nano processing technology can be achieved by cutting, micro-hole processing, surface micro-structure etching, etc.. This technology has important application value in the field of microelectronic devices, optical devices, biomedical devices and other fields.