Cutting on gratings with femtosecond lasers is a common application. Femtosecond lasers are a special type of laser with pulse durations on the order of femtoseconds (i.e., 10 minus 15 seconds). Due to their extremely short pulse duration, femtosecond lasers can achieve extremely high power densities without generating excessive heat transfer into the surrounding material and are therefore widely used in precision cutting and micromachining.

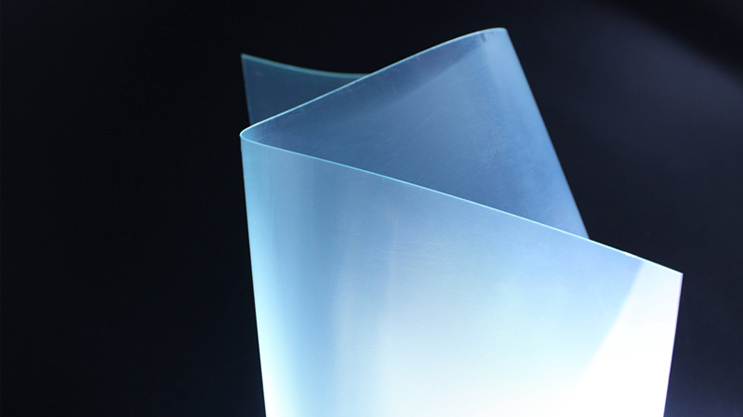

Gratings are optical elements with a periodic structure that are often used for applications such as beam splitting, wavelength selection, and optical modulation. The process of femtosecond laser cutting on gratings typically takes advantage of its extremely high precision and control, allowing for the precise etching or cutting of tiny structures or patterns on the grating surface.

The main steps in femtosecond laser cutting on gratings may include:

Design and planning: Designing the cutting pattern and parameters according to the desired grating structure and performance requirements.

Pre-treatment: Prior to actual cutting, the grating surface may need to be pre-treated, e.g. cleaned and coated, to ensure the accuracy and quality of the cut.

Laser cutting: A femtosecond laser system is used to cut the grating surface. By controlling the laser's focus position, power, pulse frequency and scanning speed, the grating can be cut accurately.

Quality Inspection: Once the cut is complete, the quality of the cut may need to be inspected to ensure that the result is as required and that the performance of the grating has not been compromised.

Cutting on gratings, femtosecond lasers can be used to create tiny structures such as miniature gratings, optical components, and more. By focusing the femtosecond laser onto the grating surface, very fine processing can be achieved, even cutting and engraving on the nanoscale. Due to the high energy density and extremely short pulse times of femtosecond lasers, the thermal effects during processing are very low, avoiding damage to the surrounding area and maintaining the high quality and precision of the grating.

The process of cutting on gratings with femtosecond lasers usually requires sophisticated optics to ensure that the laser can be focussed accurately to the desired position and that the laser's parameters need to be controlled in order to achieve the desired processing results. This processing technology has important applications in the fields of optoelectronics, micro- and nano-optics and optical communications.