Femtosecond lasers have a wide range of applications in the field of mould making and processing. Femtosecond lasers are extremely short-pulsed lasers with pulse widths typically in the femtosecond (i.e., million billionths of a second) class. This special laser characteristic gives it many advantages in etching and processing, especially in applications requiring high precision and microstructuring.

In mould and die manufacturing, femtosecond lasers can be used for the etching of microscopic patterns for fine machining of mould surfaces. Femtosecond laser etching can be used for:

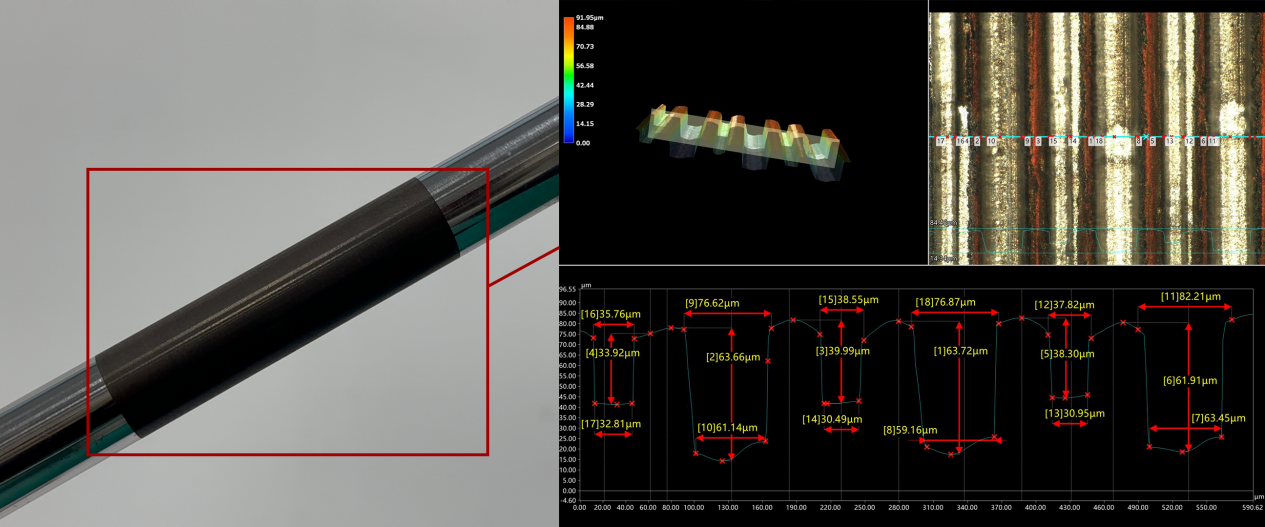

1. preparation of micro and nano structures: femtosecond laser can etch micro and even nano level structures on the surface of moulds, which can be used for the preparation of microlens arrays, microfluidic devices, micro reactors, etc.

2. Optical Mould Processing: Femtosecond lasers can be used to process the surface of optical moulds to create optical components with complex shapes and microstructures, such as lenses and gratings.

3. Mould surface modification: Femtosecond laser can be used to improve the performance of moulds through surface modification, such as increasing the surface hardness and improving the wear resistance.

4. Mould repair: Femtosecond laser can also be used for local repair when there are defects or abrasion on the surface of the mould, thus prolonging the service life of the mould.

Femtosecond laser etching has the following advantages:

1. High precision: femtosecond laser is capable of very fine processing, so highly precise moulds can be created.

2, no thermal damage: due to the extremely short laser pulse and high energy density, the processing process rarely produces a heat-affected zone, reducing thermal damage to the surface of the mould.

3, avoid micro-cracks: compared with traditional processing methods, femtosecond laser etching can reduce or avoid the formation of micro-cracks on the surface of the mould, improving the service life and durability of the mould.

4, can process a variety of materials: femtosecond laser etching technology is suitable for a variety of materials, including metals, plastics, ceramics, etc., so it has a large scope of application.

Flexibility: laser processing has a high degree of flexibility and can achieve a variety of complex shapes and microfabrication.

Femtosecond laser laser etching on moulds is a kind of advanced processing technology with high precision, low heat impact and wide applicability, which can achieve fine processing of the surface of moulds and provide an important processing means for manufacturing high-precision parts.