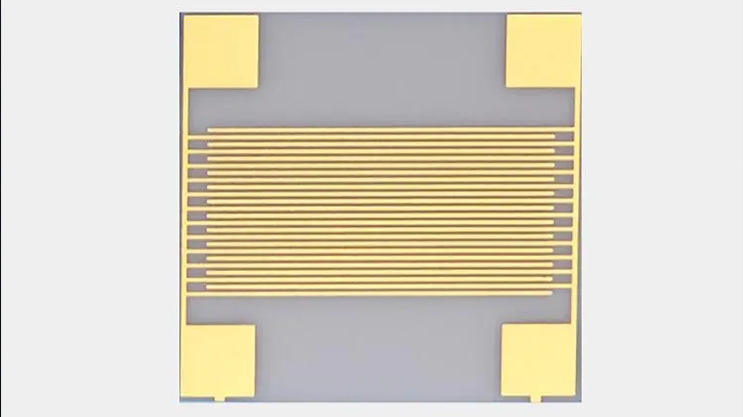

Fork-finger electrodes are electrodes with a periodic pattern within a finger or comb shaped face, such electrodes are used to generate capacitance associated with an electric field that can penetrate material samples and sensitive coatings. As a core component for electrical signal transmission, they are widely used in biomedical testing, environmental online monitoring, food safety testing, security monitoring and other important fields.

Fork Finger Electrodes

Femtosecond laser is a high-precision processing tool for manufacturing fork finger electrodes. Femtosecond lasers have extremely high precision and resolution, and can achieve micron-level processing accuracy, which is suitable for manufacturing fork finger electrodes that require high precision. At the same time, femtosecond laser processing is a non-contact processing method that does not leave mechanical scratches or residual stress on the surface of the workpiece, making it suitable for manufacturing fork finger electrodes that require a high degree of surface smoothness. The ultra-short pulse duration of femtosecond lasers means that the heat-affected zone during processing is very small, avoiding heat-induced deformation or damage to the material, which makes it suitable for the manufacture of fork finger electrodes that require a high-quality machined surface. In addition, femtosecond lasers can process a wide range of materials, including metals, ceramics, plastics, etc., and are suitable for the manufacture of fork finger electrodes made of different materials. Femtosecond laser processing also enables the manufacture of complex shapes of fork finger electrodes, as it is not limited by the shape of the process, allowing for highly personalised and customised processing.

Femtosecond laser equipment has potential and advantages in processing fork finger electrodes. Femtosecond lasers, with their ultra-short pulse times and high energy density, are capable of high-precision processing on a microscopic scale and can avoid or minimise heat-affected zones without causing thermal deformation or damage to the material. These characteristics make femtosecond lasers excel in the processing of workpieces with complex shapes and high precision requirements, which fork finger electrodes usually need to have in order to obtain accurate processing results.

Monochrome Technology Femtosecond Laser Equipment