An ion source grid is a key component used in an ion source. In an ion source, ions are generated and accelerated to a certain energy to be analysed in a mass spectrometer. The grid is usually located in a section of the ion source and is used to control the entry and exit of ions. It regulates the electric field in the ion source, which affects the generation and transport of ions. This grid can control the flux and energy of the ions by adjusting the voltage, thus optimising the performance of the mass spectrometry analysis.

Ion Source Grid

Femtosecond laser equipment has important applications in the cutting and perforating of ion source grids. The uses of femtosecond lasers for ion source grating mesh cutting and perforation include:

1. Micromachining and Cutting: Femtosecond lasers can be used to create tiny incisions and machining details in the surface of a material by focusing on an ion source grid to produce a high energy density spot. This micromachining can be used to create tiny structures such as microchips or micromechanical devices.

2. Hole Processing: Femtosecond lasers can punch holes in the ion source grid to create tiny holes or channels. These holes can be used to alter the ion flux and distribution, thereby optimising the performance and stability of the ion source.

3. Customised processing: Femtosecond laser equipment can be used to achieve customised processing results on the ion source grid by controlling the laser parameters and processing path. This kind of processing can adjust the shape, size and characteristics of the ion source grid network according to specific needs to meet different application requirements.

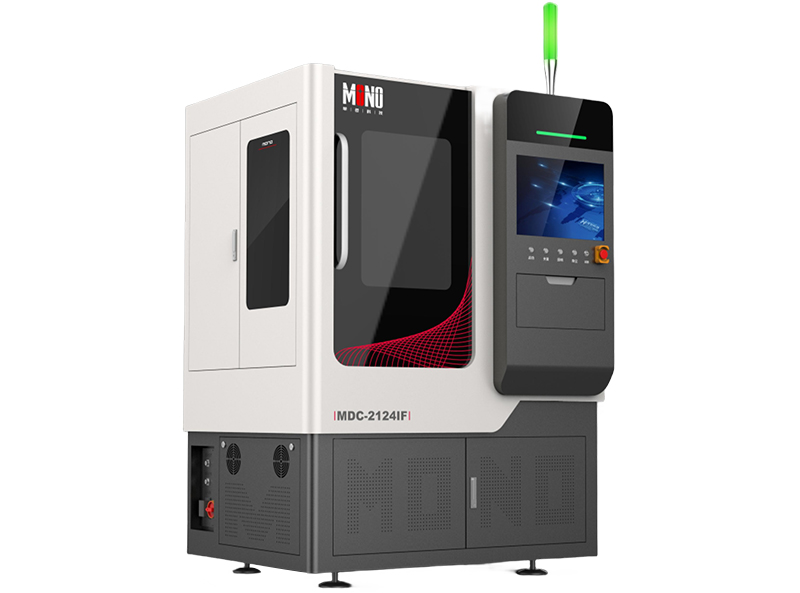

Femtosecond Laser Equipment

The use of femtosecond laser equipment for cutting and punching ion source grids makes micromachining and fabrication processes more efficient and allows for real-time monitoring and analysis of the ion source grids. Femtosecond laser processing has higher processing accuracy, less thermal impact and wider material applicability than conventional laser, mechanical, chemical etching and EDM processing, and is particularly suitable for microfabrication and high-precision machining applications.