ITO conductive glass is a special glass material with conductive properties. Its full name is Indium Tin Oxide Glass (Indium Tin Oxide), referred to as ITO glass.ITO conductive glass is usually coated with a layer of Indium Tin Oxide film on the surface of the glass, which has a high degree of transparency and conductivity, and is commonly used in the manufacture of touchscreens, liquid crystal displays, solar panels, display panels, and other electronic products.

ITO conductive glass has good transparency, making it suitable for electronic products that require transparent displays, such as LCDs and touchscreens. Indium tin oxide film gives the glass conductive properties, which can form a conductive grid or pattern on the surface for manufacturing electrodes or connecting wires for electronic devices.ITO conductive glass can be processed by cutting, drilling, and grinding like ordinary glass while maintaining its conductivity and transparency.ITO conductive glass has high chemical stability and corrosion resistance, and is able to work stably for long periods of time under various environmental conditions. ITO Conductive Glass

ITO conductive glass is mainly used in touch screens, flat panel displays, smart phones, tablet PCs, e-book readers, solar panels, electromagnetic shielding windows and other electronic products, providing these products with transparent, electrically conductive surface materials with excellent performance.

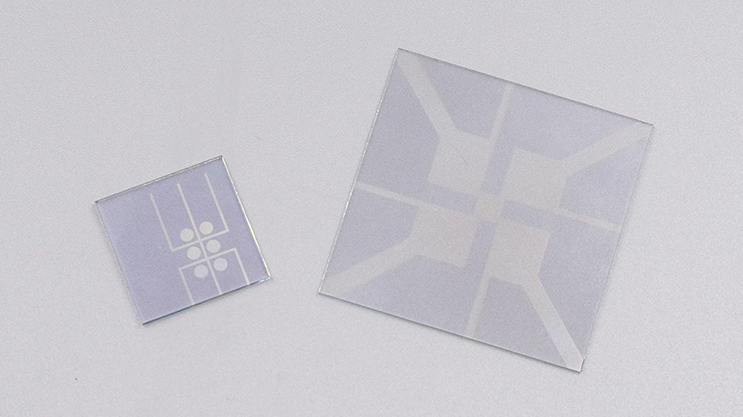

ITO conductive glass etching

Femtosecond laser processing of ITO conductive glass is a high-precision, low-thermal-impact processing method for the needs of micromachining and precision processing of conductive glass. Femtosecond lasers offer the following advantages over traditional mechanical or other laser processing methods:

Monochromatic technological femtosecond lasers are capable of very fine processing, achieving micron-level accuracy, and are suitable for creating precise conductive patterns or microstructures. The ultra-short pulse time of the femtosecond laser has almost no heat conduction effect, so there is almost no heat-affected zone during processing, avoiding thermal damage and thermal deformation. Femtosecond laser processing speed, can be completed in a short period of time complex processing tasks, improve production efficiency. Femtosecond laser can achieve a variety of processing forms, including cutting, engraving, punching, etc., with high flexibility and versatility. Since there is virtually no thermal damage or residual stress, femtosecond laser processing usually eliminates the need for subsequent heat treatment or surface treatment, saving processing costs and time. Femtosecond laser processing technology is applicable to a wide range of materials, including glass, metals, semiconductors, etc., and is not affected by the thermal conductivity or transparency of the material.

Femtosecond laser processing of ITO conductive glass is a highly efficient, precise, low-damage processing method that can meet the demand for micro-processing and precision processing of conductive glass, with a wide range of application prospects.

Monochrome Technology Femtosecond Laser Etching Equipment