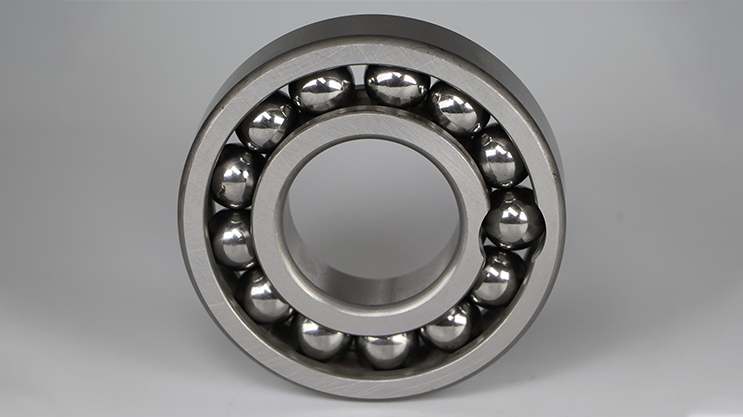

Hydraulic bearings are bearings that use hydrodynamic principles to support and reduce friction. They are commonly used in high-speed rotating mechanical equipment such as turbines, engines, pumps, etc. Hydraulic bearings reduce friction and wear by creating a film of pressurised oil on the bearing surface, thereby increasing the performance and life of the equipment at the same time. These types of bearings are usually characterised by high load carrying capacity, high rotational speed, low noise and smooth operation, and are therefore widely used in industry. Compared with conventional rolling bearings, hydraulic bearings have higher load carrying capacity and lower coefficient of friction.

Hydraulic bearings

Femtosecond laser technology for etching on hydraulic bearings is an advanced processing method. This technology utilises the extremely short duration (femtosecond level) and high energy density of femtosecond laser pulses to achieve micrometre- or even nanometre-scale processing of hydraulic bearing surfaces. By adjusting the laser parameters and the processing path, microscopic structures such as grooves, bumps or microholes can be precisely etched into the surface of hydraulic bearings to improve their properties.

Femtosecond lasers have extremely high processing accuracy and can etch out tiny structures to improve the performance and stability of hydraulic bearings. Due to the extremely short laser pulses, very little heat is generated during processing, which reduces or avoids thermal effects and deformation of the hydraulic bearing material and ensures processing quality. Femtosecond laser processing is highly controllable, and the processing parameters can be adjusted according to the needs to achieve microstructures of different shapes, sizes and densities to meet the requirements of different applications. Compared with traditional processing methods, femtosecond laser processing does not require the use of chemical solvents and coolants, which reduces environmental pollution and consumes relatively low energy.

The application of femtosecond laser etching on hydraulic bearings has a broad development prospect and can provide an effective solution for the performance optimisation and enhancement of hydraulic bearings.

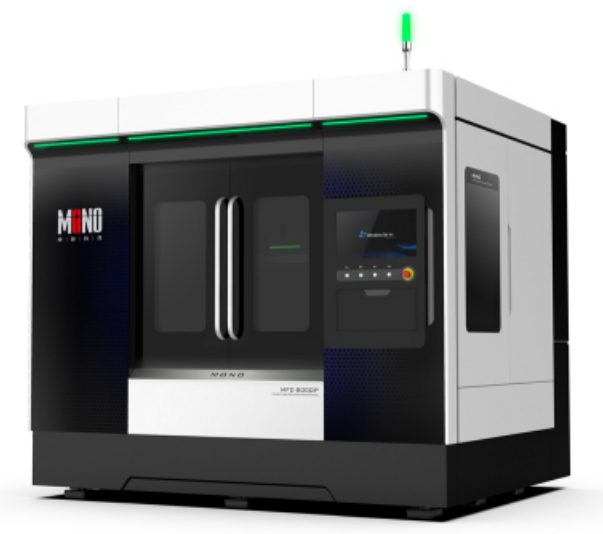

Monochrome Technology Femtosecond Laser