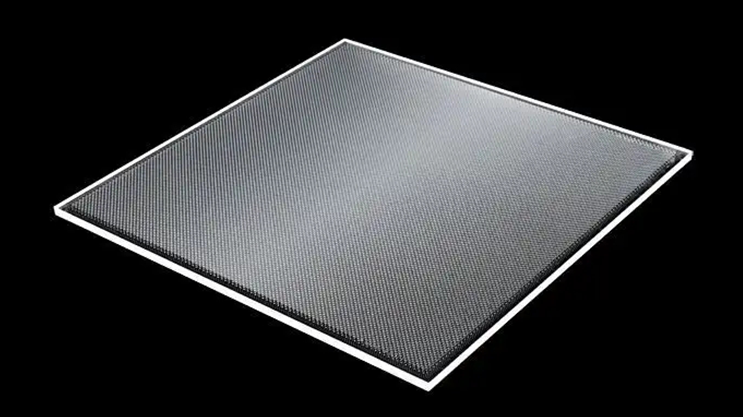

A light guide is an optical element used to transmit and distribute light. It is usually made of transparent materials such as glass, plastic or optical grade polymers with excellent optical properties and surface quality. A light guide plate directs, refracts, and disperses light from a light source to achieve specific optical functions, such as uniform illumination, beam expansion, and light path distribution.

A light guide usually has a flat surface and precise dimensions to ensure accuracy and stability in the transmission and distribution of light. Its surface may contain microstructures, such as microlens arrays, micro-convex or grating structures, to regulate the transmission and distribution characteristics of light.

In practice, light guides are widely used in LED backlight modules, LCD displays, panel lighting, optical projection and optical communications. For example, in the LED backlight module, the light guide plate can evenly distribute the light emitted from the LED to the entire display surface, improving the uniformity and brightness of the display effect.

Femtosecond laser processing on light guide plate is a high-precision processing method. Femtosecond laser processing can achieve perforation, cutting and etching, and microfabrication and structural tuning of the surface of the light guide plate, so as to improve its optical characteristics and performance.

The following steps are usually used when performing femtosecond laser processing on light guide plates:

1. Optical design: According to the product design needs and optical performance requirements, the optical design of the light guide plate. Determine the parameters such as structure, shape and size to be processed.

2. Femtosecond laser processing: the use of femtosecond laser equipment to process the surface of the light guide plate. Femtosecond laser has extremely short pulse width and high energy density, which can achieve non-thermal processing of the material and avoid thermal damage and material deformation. By controlling the parameters and processing path of the laser, micron-level processing accuracy and complex structures can be achieved on the surface of the light guide plate.

3. Structure control: Femtosecond laser processing can achieve the control of the microstructure of the surface of the light guide plate, such as the formation of micro-indentations, micro-hole arrays, micro-slots and other structures. These microstructures can improve the optical performance of the light guide plate, improve its light transmission efficiency and uniformity, reduce light loss and reflectivity.

4. Quality inspection: After processing is completed, the light guide plate is subject to quality inspection and performance testing. Check the optical properties and structural morphology of the processed surface to ensure that the processing quality and performance meet the design requirements.

Femtosecond laser processing on the light guide plate can achieve high-precision, high-efficiency and high-quality processing results, providing reliable technical support for the manufacture and application of optical devices.

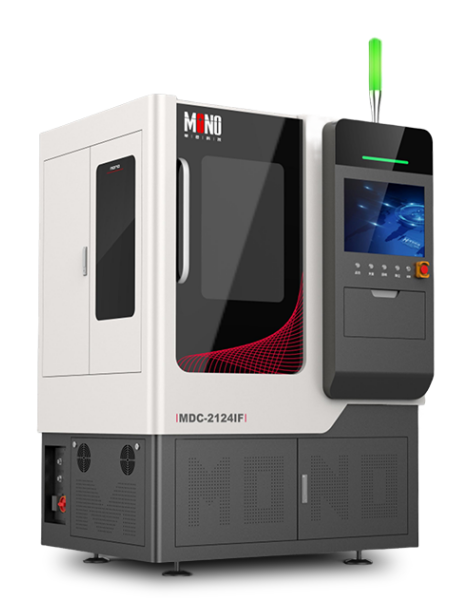

Monochrome Technology Femtosecond Laser Microvia Forming Equipment