Cellular filtration membranes are membranes used to separate and filter cells and are commonly used in biomedical laboratories, the biopharmaceutical industry, and biotechnology research. These membranes are usually made of special materials with micropores or pores that allow liquids and ions in solution to pass through while leaving cells and other macromolecules or particles on the surface of or within the membrane.

The choice of cell filtration membrane usually depends on the type and size of cells to be separated or filtered and the specific requirements of the experiment or application. Commonly used materials include polycarbonate (PC), polypropylene (PP), and polyester (PET), while pore sizes can vary between the nanometre to micron scale depending on experimental requirements. These membranes can be used alone or in combination with other experimental equipment, such as cell culture dishes, filters, etc., to meet the needs of different experiments.

Femtosecond laser technology is widely used in perforation processing of cell filtration membranes, and its unique advantages are its high precision and non-thermal processing characteristics. During the perforation process, the femtosecond laser equipment accurately focuses the light energy to the target position on the surface of the cellular filtration membrane by means of high-energy pulses, thus creating tiny holes.

By controlling the energy density of the laser and the movement of the focusing point, precise control of the holes, including pore size, shape and density, can be achieved. This makes femtosecond laser technology ideal for preparing customised cellular filtration membranes with specific pore sizes and layouts.

Femtosecond laser perforation offers the following advantages over traditional machining or chemical etching methods:

High Precision: Femtosecond lasers are capable of micron-level precision machining, ensuring accuracy and consistency in pore size and shape.

Non-thermal: Due to the extremely short laser pulses and high energy density, femtosecond laser perforation is virtually thermally neutral, causing no thermal damage or distortion to the cellular filter membrane.

No Moulds Required: Femtosecond laser perforation does not require the use of moulds, thus allowing for flexible design and customisation, saving time and costs.

Optical Transparency: Femtosecond lasers have good transparency for most materials, so optically transparent cellular filtration membranes can be processed.

After femtosecond laser perforation, the holes in the cellular filtration membranes are clearly visible, well formed, and have a consistent size and distribution. These pores facilitate cell aeration and nutrition, while maintaining the membrane's filtration properties and structural stability, providing convenience and support for cell culture and isolation.

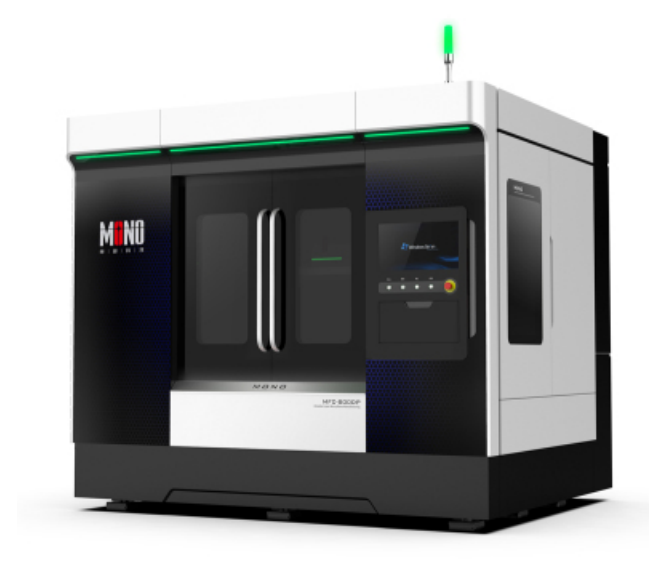

Monochrome Technology Femtosecond Laser Microvia Forming Equipment