Air bearing is a special type of bearing that uses the air pressure of a gas to support a rotating bearing or moving part, thereby reducing friction and wear. Compared with traditional lubricated grease bearings, air bearing has lower friction, higher speed and longer service life.

Air bearing usually consists of two parts: a fixed part and a floating part. The fixed part is usually mounted on the rack or base, while the floating part is directly attached to the rotating shaft or moving parts. In the gap between bearings, the floating part is supported by the gas static pressure generated by the compressed gas (such as air or nitrogen), so that it is out of direct contact with the fixed part, thus achieving almost frictionless movement.

Air bearing has many advantages, including high-speed operation, low friction, low wear, no lubrication, no maintenance and so on. Therefore, it is widely used in high-speed rotating equipment, precision machining machine tools, optical instruments, maglev trains and other fields.

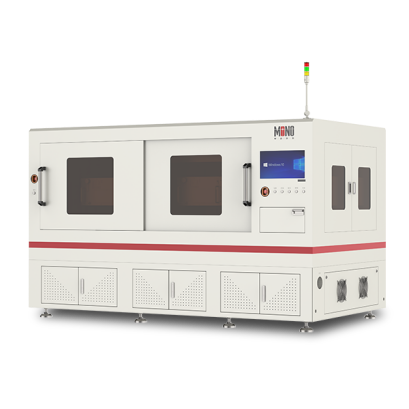

A femtosecond laser is a special type of laser whose pulse width is on the order of femtosecond (1 femtosecond =10^-15 seconds). Compared with traditional lasers, femtosecond lasers have a very short pulse time and can release a large amount of energy in a very short time. This makes femtosecond lasers have unique application value in material processing, precision machining, optical imaging, medical treatment and other fields. Femtosecond laser equipment can perform the following processing on air bearing:

1. Microhole processing: Femtosecond laser can make microholes on the surface of the air bearing to adjust the gas flow and pressure distribution, thereby improving the bearing performance.

2. Surface treatment: The femtosecond laser can fine treat the surface of the air bearing, including removing the oxide layer, adjusting the surface roughness, improving the surface lubricity, etc., to improve the service life and performance of the bearing.

3. Microstructure processing: Through femtosecond laser processing, microstructure is manufactured on the surface of the air bearing, such as micro-grooves, micro-bumps, etc., which can improve the gas flow and lubrication effect and reduce friction loss.

4. Precision etching: The femtosecond laser can achieve precision etching of the surface of the air bearing to create complex patterns or structures to improve the performance and stability of the bearing.

Femtosecond laser processing on air bearing can improve bearing surface characteristics, reduce friction loss, improve bearing performance and stability.