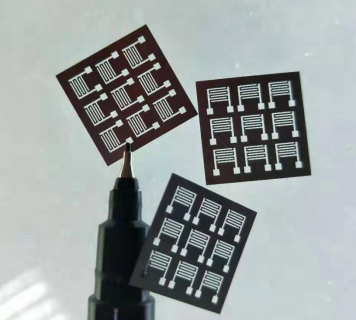

A mask plate is a tool used to make a microscopic structure, usually consisting of a transparent substrate and a light-sensitive material covered on its surface. During manufacturing, the photosensitive material undergoes a chemical reaction or change in the area exposed to light to form the desired structure. With the mask plate, precise control of the microstructure and efficient production can be achieved.

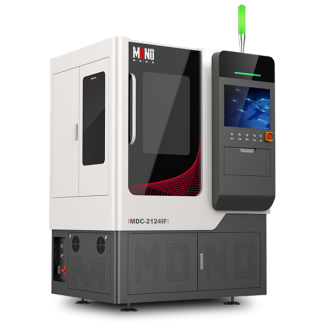

The femtosecond laser can carry out micro-machining on the mask plate, including the etching or engraving of micro-structures such as micro-holes, micro-grooves and micro-bumps.

Its advantages are mainly reflected in the following aspects:

1. High-precision processing: the femtosecond laser pulse is extremely short, which can achieve the processing accuracy of nanometer level, and can create extremely fine microstructure.

2. Non-contact processing: femtosecond laser processing process does not need to contact the surface of the workpiece, to avoid damage or deformation caused by contact, suitable for non-contact processing of fine structures.

3. No thermal effect: the femtosecond laser pulse time is very short, the thermal effect generated during the processing is very small, avoiding the thermal damage and deformation of the material, which is suitable for precision machining of photosensitive materials.

4. Flexibility and complex structure processing: femtosecond laser processing technology has a high degree of flexibility, which can realize the processing of complex microstructures and micro-patterns to meet the design needs of different mask plates.

5. High efficiency processing: femtosecond laser processing speed, high processing efficiency, can achieve large-scale production, suitable for the industrial production process of micro structure manufacturing.

Femtosecond laser processing on the mask plate has the advantages of high precision, non-contact, no thermal effect, flexibility and high efficiency, which is suitable for micro-structure manufacturing and micro-machining.