A star point plate is an optical part with small holes for light transmission, usually used to simulate a point light source. It has a wide range of applications in optical instruments, such as microscopes and spectrometers.

The main feature of the star point plate is that the small holes on it are very small, usually around 0.05mm in diameter. The imaging quality of an optical system can be assessed by placing the star point plate on the object side and observing the shape and size of the resulting image with a microscope.

In practice, the star point plate can help to check the resolution, aberration and other performance indicators of the optical system. The smaller the diffraction pattern of the object point and the more concentrated the energy, the better the imaging quality of the system.

Optical Starpoint Plates

The use of femtosecond lasers to punch holes in star point plates is an advanced processing technique. Femtosecond lasers have ultra-short pulse widths and extremely high peak powers, which allow them to interact with materials in a very short time for very fine and precise processing.

When a femtosecond laser is applied to a star point plate, extreme conditions such as high temperatures and pressures can be rapidly generated in a very small area, enabling perforation operations. This type of perforation has a high degree of precision and a very small heat-affected zone, which avoids problems such as large thermal damage and deformation of the surrounding material and ensures the performance and quality of the star point plate. At the same time, by precisely controlling the laser parameters and processing conditions, holes of different sizes and shapes can be obtained to meet specific application requirements.

Femtosecond laser drilling holes in star point plates has the following main advantages:

1. Ultra-high precision: very fine and dimensionally accurate holes can be punched, which can well meet the high requirements for small holes in star point plates.

2. minimal thermal impact: almost no thermal diffusion, which maximises the performance and structural integrity of the star point plate material.

3. No material splash: the punching process is clean and clear, no material fragments, etc. will affect the quality and subsequent use of the star point plate.

4. Repeatability: Stable punching of holes with good consistency ensures the consistency of the quality of the star point plate.

5. Can process complex shapes: according to the need to punch a variety of special shapes of holes, adapt to different application scenarios.

6. Fast processing speed: it can complete the punching operation efficiently and improve the production efficiency.

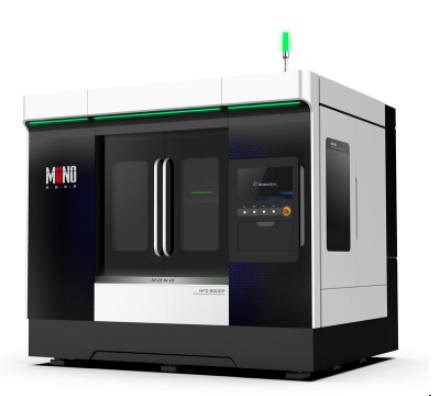

Monochrome Technology Femtosecond Laser Microporous Processing Equipment