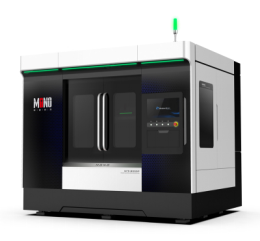

Femtosecond laser is a kind of laser with very short pulse width, and its pulse width can reach the femtosecond level, that is, ten to the minus fifteen seconds. This ultra-short pulse time allows the laser energy to be released in a very short period of time, enabling high-precision machining. When making microholes in PET and PI films, the femtosecond laser can achieve non-contact processing of the material surface by precisely controlling the pulse energy and focusing position of the laser.

For heat sensitive materials such as PET film and PI film, traditional processing methods often cause thermal damage to the material, resulting in material performance degradation or deformation. However, femtosecond laser processing can effectively avoid this problem. Because the pulse width of the femtosecond laser is extremely short, the action time of the laser energy inside the material is extremely short, so the heat generated can quickly spread to the surrounding environment, without causing obvious thermal damage to the material. In addition, femtosecond laser processing also has the characteristics of high precision and high resolution, which can achieve precise control of the shape and size of the microhole.

Femtosecond laser processing has other significant advantages when it comes to making microholes in PET and PI films. First, because there is no need to contact the surface of the material during processing, damage to the material caused by mechanical stress can be avoided. Second, the thermal affected zone of femtosecond laser processing is very small, usually only in the micron level, which means that there is no significant thermal effect on the surrounding material during processing. Finally, femtosecond laser processing does not require the use of chemical agents or additives, so environmental pollution and changes in material properties can be avoided.

In practical applications, the technology of femtosecond laser to punch microholes in PET and PI films has been widely used. For example, in the field of electronic packaging, PI film, as a high-performance insulation material, is widely used in circuit boards, chip packaging and other occasions. Through the femtosecond laser microhole technology, the required microhole structure can be precisely machined on the PI film, so as to meet the demand for high-precision and high-reliability machining in the field of electronic packaging. In addition, in the biomedical field, PET and PI membranes are also widely used in the manufacture of medical devices, biosensors and other products. By using femtosecond laser microperforation technology, the surface microstructure of these materials can be accurately processed, thereby improving the performance and reliability of the product.

However, despite the many advantages of the femtosecond laser technology for microperforating PET and PI films, there are still some challenges and limitations in practical applications. For example, femtosecond laser equipment is costly and requires professional operation and maintenance personnel. In addition, for different materials and processing needs, laser parameter optimization and process adjustment need to be targeted. Therefore, in practical applications, it is necessary to comprehensively consider factors such as processing needs, cost effectiveness and technical feasibility, and select suitable processing methods and equipment.

The technology of femtosecond laser to punch microholes in PET and PI films brings a new solution to the field of material processing. By precisely controlling the laser parameters and processing conditions, the surface microstructure of the material can be accurately machined to meet the needs of high-precision and high-reliability machining in different fields. With the continuous progress of technology and the reduction of cost, it is believed that this technology will be more widely used and developed in the future.