A femtosecond laser is a laser technology with extremely short pulse durations, usually on the order of femtoseconds (10^-15 seconds). It is widely used in micromachining and material handling, especially in fine pattern etching. Etching patterns on silicon nitride (Si₃N₄) using a femtosecond laser has several advantages:

1. High precision: Due to the extremely short pulse time of the femtosecond laser, the heat affected zone (HAZ) of the material is very small, and high precision etching can be achieved.

2. Low thermal effect: the femtosecond laser pulse time is short, the energy is concentrated, and the thermal diffusion of the material is reduced, thus reducing the thermal damage and thermal deformation.

3. Suitable for a variety of materials: femtosecond lasers can effectively process a variety of materials, including metals, ceramics, semiconductors and insulators.

4. Non-contact processing: Laser etching is a non-contact processing method that can avoid mechanical stress on the surface of the material.

Femtosecond laser etching silicon nitride steps:

1. Sample preparation: The silicon nitride sheet is prepared and cleaned to remove surface impurities.

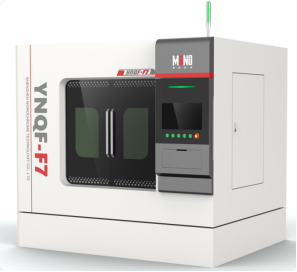

2. Laser parameter setting: Adjust the parameters of the femtosecond laser, including pulse energy, pulse repetition rate, scanning speed, etc., to achieve the best etching effect.

3. Pattern design: Use computer aided design (CAD) software to design the required etched pattern.

4. Laser etching: Input the designed pattern into the femtosecond laser etching device through the control system and start etching.

5. Post-treatment: After the etching is completed, the sample is cleaned and treated as necessary to remove residue and improve surface quality.

Application field:

1. Microelectronics: femtosecond laser etching technology can be used to make precision structures in microelectronic devices, such as micro circuits, nanodevices, etc.

2. Photonics: Precision pattern etching can be carried out in photonic devices such as silicon nitride waveguides and gratings.

3. Biomedical: Used to make microfluidic chips and other biomedical devices.

The technical advantages of femtosecond laser etching of silicon nitride make it have important application value in micro-nano machining with high precision and high quality.