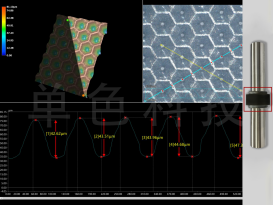

Application of etched textures and microstructures on roller surfaces:

1. Surface functionalisation: By etching specific microstructures on the surface of the rollers, the surface characteristics can be changed, such as improving surface hardness, wear resistance and lubrication properties.

2. Friction reduction and lubrication: The etched microstructure can effectively reduce friction, increase lubrication effect and extend the service life of the roller.

3. Improvement of contact performance: By controlling the shape and distribution of the surface microstructure, it can improve the contact performance between the roller and other materials, and improve the processing accuracy and efficiency.

4. Anti-fouling and self-cleaning: specific surface microstructure can give the roller surface anti-fouling and self-cleaning function.

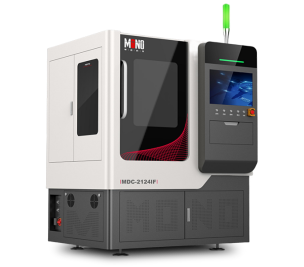

Femtosecond laser etching texture and microstructure etching on roller surfaces is an advanced processing technology with the following characteristics and applications:

1. Ultra-short pulse width: The pulse width of femtosecond laser is usually at the level of 10^-15 seconds, which allows the laser energy to be released centrally in a very short period of time, which reduces the thermal effect and avoids extensive thermal damage to the material.

2. High Peak Power: Because the pulse energy is released in a very short period of time, femtosecond lasers have extremely high peak power, which can instantly evaporate the material and achieve high precision processing.

3. Non-linear effects: Femtosecond lasers can produce non-linear effects such as multi-photon absorption within the material, making it possible to process transparent or low-absorption materials.

Advantages of femtosecond laser etching:

1. High precision: femtosecond laser is capable of achieving nanometre-level processing precision, which is suitable for fine processing of microstructures.

2. Low heat-affected zone: Since the heat-affected zone in femtosecond laser processing is extremely small, it can reduce thermal damage and deformation of materials.

3. Multi-material applicability: Femtosecond laser can process a variety of materials, including metals, ceramics, glass and polymers.

Femtosecond laser technology has significant advantages and a wide range of application prospects for etching texture and microstructure on roller surfaces, which can significantly enhance the functionality and performance of material surfaces.