Mould is an indispensable and important tool in industrial production, which is widely used in the fields of home appliances, automobiles, electronic equipment and medical devices. The texture and pattern on the surface of the mould plays a crucial role in the quality and appearance of the product. With the improvement of consumer consumption level, the traditional mould etching processing method has certain limitations, unable to meet the requirements of high-end products on the fineness and complexity of the texture. The emergence of mould laser etching technology has brought new possibilities for mould surface treatment.

Sun pattern is a common process of mould surface treatment, also known as mould biting flower, mould etching and mould etching, with lower process cost, rich effect, fast speed and other characteristics, so it is widely used.

The use of femtosecond laser to etch precise patterns and textures on the surface of moulds and dies, through the analysis of its practical applications in the fields of automobiles, electronic equipment and medical devices, etc., verifies that the laser etching technology can significantly improve the surface quality and performance of the products, increase the productivity, and at the same time, have the characteristics of environmental protection.

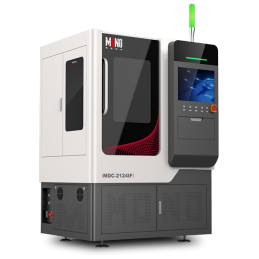

Femtosecond laser for mould texture nibbling processing is a high-precision, non-contact surface processing technology. Femtosecond laser (femtosecond laser) has an ultra-short pulse width (usually on the order of 10^-15 seconds), which gives it a unique advantage in material processing.

Femtosecond laser for mould texture nibbling processing is an advanced processing technology with the following characteristics:

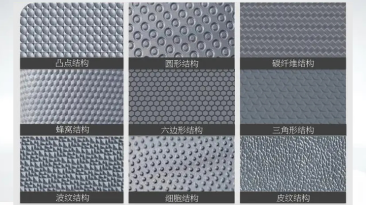

High precision: Femtosecond laser can achieve micron-scale processing precision, capable of etching very precise patterns and textures on the surface of moulds.

High Flexibility: Complex 2D or 3D texture processing can be achieved by computer control of the laser path and parameters.

High efficiency: the ability to quickly etch textures on the surface of moulds improves productivity.

Environmentally friendly: Femtosecond laser processing does not produce chemical waste liquid and other pollutants, which is friendly to the environment.

Good reproducibility: the processing parameters can be reused and the consistency of the mould is high.

Femtosecond laser mould texture nibbling processing technology has become an important processing means in modern manufacturing industry due to its high precision, high efficiency and wide applicability.