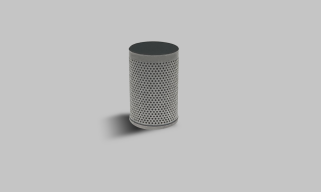

In the fields of internal combustion engines, gas turbines, etc., the performance of fuel injectors is directly related to combustion efficiency and equipment life. The fuel injector filter made with laser drilling technology not only brings excellent filtering effect to the fuel system, but also achieves higher precision and innovation in design.

The fuel injector is an important component in the fuel system. Its function is to atomize the fuel into tiny particles and spray them into the combustion chamber to improve the combustion efficiency. To ensure the normal operation of the fuel injector, the design of the fuel injector filter is very important. It can effectively prevent foreign objects such as impurities and particles from entering the fuel injector and ensure the purity of the fuel.

In the manufacturing process of the fuel injector filter, femtosecond laser technology can punch uniform and precise holes on the extremely small filter structure. The diameter of these holes is usually at the micron level, which can effectively filter tiny impurities and ensure the working efficiency and service life of the fuel injector. By magnifying the microscopic image, it can be clearly observed that the edges of the holes processed by femtosecond laser are very smooth and neat, with extremely high size and position accuracy, meeting strict manufacturing requirements.

Femtosecond laser drilling of holes in fuel injector filters is a highly precise processing technology that is widely used in the automotive, aerospace and other high-precision machinery fields.

The principles and advantages of femtosecond laser drilling

Ultrashort pulse duration: The pulse duration of a femtosecond laser is on the order of 10^-15 seconds, which can release a large amount of energy in a very short time.

High peak power: The pulses are extremely short but have a very high energy density to remove material.

Minimal heat-affected zone: Due to the short pulse time, femtosecond laser has almost no heat conduction effect, reducing thermal damage to the material.

High precision: Femtosecond laser can achieve sub-micron level processing accuracy, which is very suitable for micro-hole processing.