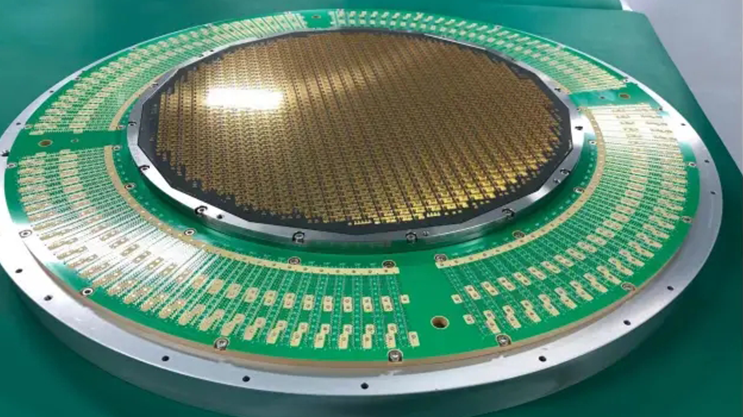

Semiconductor probe card is a key device used to test and verify the electrical performance of semiconductor chips. It is mainly used to perform electrical tests at different stages of chip manufacturing to ensure that the function and performance of the chip meet the design requirements before it is put on the market.

A semiconductor probe card is an interface tool that connects the test equipment and the chip under test ( DUT ). The probe card is equipped with multiple probes, which contact the test points on the chip to achieve the transmission and testing of electrical signals.

Structure and composition

1. Probe: A tiny needle-like component mounted on a probe card that contacts pads or pins on a chip. Probes are usually made of high-strength, wear-resistant materials such as tungsten or nickel.

2. Substrate: The base of the probe card, usually made of ceramic or printed circuit board (PCB) material, used to support and fix the probes.

3. Brackets and frames: Used to fix the probe card and ensure its stability for easy alignment during testing.

4. Connector: The part that connects the probe card to the test equipment to ensure the stability and accuracy of signal transmission.

Semiconductor probe cards play a vital role in chip testing and verification. They ensure that chips are rigorously tested and meet design and performance requirements before entering the market through electrical contact and signal transmission. As semiconductor technology continues to advance, probe cards are also evolving to meet the increasingly complex and high-density chip testing needs.

The application of femtosecond laser on probe cards is mainly concentrated in the field of precision processing. Probe cards are key components used to test the electrical performance of semiconductor chips. Femtosecond laser technology can perform a variety of precision processing during the manufacturing process of probe cards. The following are the main processing that femtosecond laser can do on probe cards:

1. Micro hole processing

Micro-holes are drilled on the probes of the probe card to install wires or make electrical connections. Femtosecond lasers can achieve sub-micron-level aperture control to ensure the size and position accuracy of the holes.

2. Microstructure Etching

Etch complex microstructures on the surface of the probe card to improve electrical contact performance or achieve specific functional design. Femtosecond lasers can carve complex patterns without damaging surrounding materials.

3. Precision cutting

Cut the probe card material to meet specific shape and size requirements. Femtosecond laser cutting has the characteristics of high precision and low heat-affected zone, which can prevent material deformation and damage.

Monochrome Technology Femtosecond Laser Drilling and Cutting Equipment

Femtosecond lasers can perform a variety of precision processing on probe cards, including micro-hole processing, micro-structure etching, precision cutting, etc. These processing technologies can significantly improve the manufacturing accuracy and performance of probe cards and meet the requirements of modern semiconductor test equipment for high precision and high reliability.