A diaphragm (or diaphragm) is an optical element, usually made of metal or optical material, used in optical systems to control the transmission and shape of light. Its primary function is to limit light in the optical path, preventing unwanted scattering or interference and thus improving the performance of the optical system. As an important component of an optical system, the diaphragm plays a key role in controlling and optimising the optical path and is essential for achieving high quality optical imaging and beam management.

The materials used to manufacture diaphragms are usually chosen to have good optical properties and mechanical strength, such as metals (e.g. aluminium, stainless steel), optical glass or special optical coating materials. Different diaphragms can be designed with aperture sizes, shapes and surface treatments to meet the requirements of the optical system for specific applications.

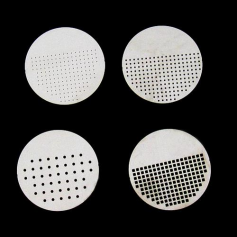

In the manufacture of diaphragm sheets, femtosecond lasers can be used to punch, cut, etch and form complex geometries as well as to achieve micron-level surface smoothness. These properties make femtosecond lasers one of the most important tools for manufacturing high-precision optical components.

Femtosecond lasers are a special type of laser with extremely short pulse durations (in the femtosecond class, i.e., on the order of 10^-15 seconds), which enables very fine processing. Femtosecond laser processing has the following advantages over conventional laser processing techniques:

1. High precision: Micron and even sub-micron precision processing is possible, making it suitable for the manufacture of high-precision optical components.

2. Less heat-affected area: During femtosecond laser processing, the heat-affected area is very small, there is almost no thermal deformation or thermal damage, which will not have a negative impact on the quality of optical components.

3. Non-contact processing: The laser beam does not contact the surface of the workpiece during processing, so it will not introduce mechanical damage or contamination, which ensures the high quality of the processed surface.

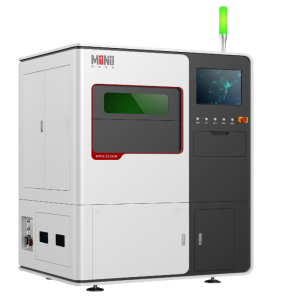

Monochrome Technology femtosecond laser processing diaphragm sheets are widely used in many fields, such as:

1. Microscopes and optical instruments: High-precision diaphragms are used in microscopes to control the shape and size of the light beam and improve the imaging quality.

2. Laser systems: Diaphragms used in laser cavities to control the laser mode and beam quality.

3.Optical communication: In optical fibre communication system, diaphragm is used to regulate and control the optical signal.

Monochrome Technology Femtosecond Laser Processing diaphragm sheet has become one of the preferred technologies for manufacturing high-performance optical components due to its advantages of high precision, low thermal impact and non-contact processing.