A printer piezo printhead diaphragm is part of the piezo printhead in an inkjet printer and is used to control the ejection of ink droplets. Piezo printheads utilise the piezoelectric effect by applying a voltage that deforms the piezoelectric material, which creates pressure and extrudes ink droplets. The diaphragm plays a key role in this process.

Principle of operation of piezoelectric printhead diaphragms:

1. Piezoelectric effect: Piezoelectric materials (such as piezoelectric ceramics or piezoelectric crystals) are mechanically deformed when a voltage is applied. This deformation causes pressure changes in the ink chamber.

2. Diaphragm deformation: The diaphragm is connected to the piezoelectric material, and when the piezoelectric material deforms, it drives the diaphragm to deform together. The deformation of the diaphragm will compress the ink chamber, thus extruding ink droplets.

3. Droplet ejection: Through the rapid deformation and recovery of the diaphragm, the formation and ejection of ink droplets are controlled. The fine control ability of the diaphragm directly affects the drop size, speed and direction.

Piezo printhead diaphragm material:

Diaphragms are typically made of materials with high strength and toughness to ensure reliability and longevity at high frequencies and pressures. Common materials include:

- Metallic films: such as stainless steel foils, which have good mechanical strength and durability.

- Polymer films: such as polyimide (PI) for good flexibility and chemical resistance.

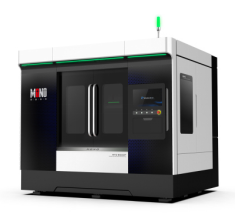

Femtosecond laser technology can be used to make small holes in printer piezo printhead diaphragms. Monochromatic technology femtosecond lasers with extremely high precision and short pulse durations are able to process small and precise apertures without damaging the surrounding material. This technology has great advantages in micromachining and microstructure fabrication.

Advantages of Monochrome Technology Femtosecond Laser Technology

1、High precision processing

Monochrome technology femtosecond laser technology can achieve very high processing accuracy, applicable to micron or even sub-micron level aperture processing. This high-precision processing for inkjet printers piezoelectric printhead diaphragm is particularly important, because the accuracy of the aperture directly affects the size, speed and direction of the ink droplets, thus affecting the print quality.

2, low thermal impact

The extremely short pulse duration of the femtosecond laser allows the material to absorb very little heat during processing, thus reducing the heat affected zone (HAZ). This helps avoid thermal damage to the diaphragm material and ensures stability of material properties and structure.

3、No mechanical stress

Since femtosecond laser processing is non-contact, it does not exert any mechanical stress on the diaphragm, thus avoiding the deformation and damage that may be caused by mechanical processing. This is particularly important for thin-film materials, as they are usually fragile and susceptible to mechanical stress.

4. Unlimited materials

Monochrome Technology femtosecond laser technology is suitable for the processing of a wide range of materials, whether they are metal films, polymer films or multilayer composites, and can achieve high-precision aperture processing.

Monochrome Technology femtosecond laser technology provides an ideal solution for piezoelectric printhead diaphragm processing through the advantages of high precision, low thermal influence, no mechanical stress and unlimited materials. The technology not only enhances the processing quality and performance of the diaphragm, but also expands its applicability in a wide range of materials and applications, providing strong support for the development of inkjet printing technology.