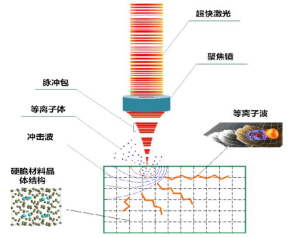

Femtosecond laser equipment can be used to process micro, small and fine holes. Femtosecond laser technology is ideally suited for the processing of tiny and complex structures due to its high precision and extremely short pulse duration.

The following are the advantages of femtosecond laser equipment in micro, small and fine hole processing:

1. High precision:

Femtosecond lasers can achieve micron or even nanometer processing accuracy, which is very suitable for microvia, small hole and fine hole processing that requires extremely high precision. Compared with traditional processing methods, femtosecond lasers can precisely control the laser energy and focus position, resulting in more accurate processing results.

For example, in the manufacture of microfluidic chips, femtosecond lasers can process microvias with a diameter of only a few micrometers, ensuring precise control and transmission of fluids.

2. Minimal heat-affected zone:

Due to the extremely short pulse duration of femtosecond lasers, the heat-affected zone is very small, avoiding thermal damage and material deformation. This is particularly important for processing fine structures. Conventional laser processing tends to produce large heat affected zones, leading to thermal deformation and degradation of material properties.

For example, in semiconductor manufacturing, femtosecond lasers can avoid wafer surface damage due to thermal effects, maintaining the high performance and reliability of the chip.

3. Burr-free and high finish:

The edges after femtosecond laser cutting are so smooth that no additional post-processing steps are required. This results in high-quality edges on processed microvias, small holes and fine vias, improving product performance and aesthetics.

For example, in the manufacture of optical devices, femtosecond lasers ensure smooth, burr-free edges on lenses and prisms, thus optimizing optical performance.

4. Material Versatility:

Femtosecond lasers can process a wide range of materials, including metals, glass, ceramics, polymers and composites. This makes it widely applicable in a variety of applications. Femtosecond lasers provide excellent processing of both hard and brittle materials as well as flexible materials.

For example, in medical device manufacturing, femtosecond lasers can process biocompatible polymers to create fine medical sensors and microneedles.

5. Non-contact processing:

Femtosecond laser processing is non-contact and does not apply mechanical stress to the material, avoiding deformation and damage to the material due to mechanical stress. This characteristic makes femtosecond lasers particularly suitable for processing fragile and sensitive materials.

For example, in the aerospace field, femtosecond lasers can process lightweight composites without causing mechanical damage to the material, ensuring high strength and lightweight parts.

Fields of application

1. Semiconductor manufacturing:

In semiconductor manufacturing, femtosecond lasers can be used to process microvias and fine holes on chips to enable high-density circuit design and precision microstructures. Femtosecond lasers can process tiny vias and via holes to meet the needs of advanced packaging technologies.

For example, in the fabrication of 3D NAND flash memory, femtosecond lasers can accurately etch microvias with high aspect ratios to achieve high storage densities.

2. Micro-Electro-Mechanical Systems (MEMS):

In MEMS devices, femtosecond lasers can be used to fabricate tiny mechanical structures and microvias to enhance system performance and reliability. Femtosecond lasers can process structures such as fine micro-cantilever beams, micro-gears and micro-channels.

For example, in the fabrication of microfluidic sensors, femtosecond lasers can process high-precision microholes to ensure the sensitivity and accuracy of the sensors.

3. Biomedical engineering:

In the biomedical field, femtosecond lasers can be used to fabricate microvias and fine holes in microfluidic chips and biosensors for high-precision bioanalysis and diagnosis. Femtosecond lasers can process biological materials without damage, preserving their biological activity.

For example, in the fabrication of DNA sequencing chips, femtosecond lasers can process precise microvias for high-throughput gene sequencing.

4. Aerospace:

In aerospace, femtosecond lasers can be used to create high-precision microvias and fine holes to meet the high-performance requirements of special parts. Femtosecond lasers can process high-strength, lightweight structures to enhance the performance of the vehicle.

For example, in spacecraft cooling systems, femtosecond lasers can process micro-hole structures for efficient thermal management.

5. Optical devices:

In the field of optics, femtosecond lasers can be used to process microvias and fine holes in optical components to achieve specific optical properties and functions. Femtosecond lasers can process components such as gratings, microlenses and fiber optic connectors with high precision.

For example, in optical communication equipment, femtosecond lasers can process fine fiber-optic connection holes for low-loss optical signal transmission.

Monochrome Technology femtosecond laser devices are used in a wide variety of applications requiring micro, small and fine hole processing due to their high precision, low thermal impact and wide material adaptability. Whether in semiconductor manufacturing, MEMS, biomedical engineering, or aerospace and optical device manufacturing, femtosecond lasers have shown unrivaled advantages and potential.