There are major difficulties and challenges in making through holes with diameters below 20 μm using conventional methods. For example:

1. Mechanical drilling

- Accuracy limitation: It is difficult to achieve 20μm accuracy with conventional mechanical drilling, and tool wear can lead to uneven hole diameters.

- Thermal effects: The drilling process generates heat, which can cause deformation or damage to the material, especially for heat-sensitive materials.

- Limited material selection: Some hard or brittle materials are difficult to process with high precision through mechanical drilling.

2. Conventional laser drilling

- Heat affected zone (HAZ): The long pulse time of nanosecond or picosecond lasers tends to produce a large heat affected zone, leading to material deformation or ablation.

- Accuracy and quality: Hole diameter and edge quality may not be as expected.

3. Chemical etching

- Etching uniformity: chemical etching is difficult to ensure the uniformity and consistency of the aperture, especially at the μm level.

- Material compatibility: different materials require different etchant and process, and chemical etching may not be suitable for some materials.

- Environmental and safety issues: Chemical etching requires handling of corrosive chemicals and has high environmental and operator safety requirements.

When making 20μm diameter through-holes, femtosecond lasers are often the preferred choice due to their high precision, low thermal impact and wide material adaptability.

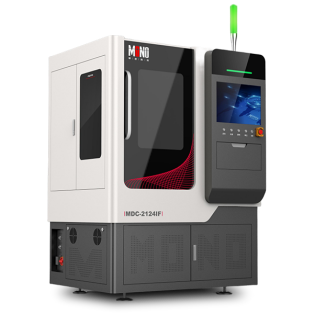

Monochrome Technology femtosecond laser processing equipment has the following features and advantages:

1. Ultra-fast pulses: Femtosecond laser pulse durations are extremely short, typically on the order of 10^-15 seconds. Due to the extremely short pulse duration, the laser energy can be concentrated in a very small area, resulting in high precision material removal.

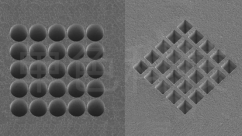

2. High precision: The high energy density of femtosecond lasers makes it possible to create very fine structures in the material, such as 20-μm diameter holes. Femtosecond lasers allow for smaller feature sizes and higher machining accuracy than traditional machining methods.

3. Cold processing: Due to the extremely short duration of the femtosecond laser pulse, the energy absorbed by the material is not transmitted to the surrounding area in time, thus reducing the heat affected zone (HAZ). This means that the material will not be thermally deformed or damaged by laser processing, which is particularly suitable for heat sensitive materials.

4. Multi-material adaptability: Femtosecond laser can be used to process a wide range of materials, including metals, semiconductors, ceramics and polymers. Its performance on different materials is stable and adaptable.

5. Non-contact processing: Femtosecond laser is a non-contact processing technology without the problems of mechanical wear and tool abrasion, thus improving the consistency and reliability of processing.

6. Efficient and fast: Although the single pulse energy of femtosecond laser is very low, fast and efficient material removal and processing can be realized by high-speed repetitive pulses.

Femtosecond laser drilling of through holes in materials with diameters of 20 μm or less is an efficient, precise and versatile micromachining technique for a wide range of high-precision manufacturing needs.