Femtosecond laser etching on rollers is a precision machining technology that is widely used in various industries for its high precision, high efficiency and high quality.

I. Technical principle

Femtosecond laser technology utilizes ultrashort pulses (on the order of 10^-15 seconds) for material processing. Its main features include:

- Non-linear absorption: Ultrashort pulses cause the material to absorb a large amount of energy in a very short period of time, resulting in localized ionization and dissociation of the material surface and the formation of a plasma.

- Cold Processing: Due to the extremely short pulse duration, the laser-material interaction is completed before thermal diffusion, resulting in non-thermal processing and a reduced heat affected zone (HAZ).

- High Peak Power: Femtosecond lasers have extremely high peak power, enabling fine micron and even nanometer scale processing.

II. Specific processes

1. Material selection:

- Femtosecond lasers are capable of etching a wide variety of materials, including metals (e.g., steel, aluminum, copper), ceramics, polymers, and so on. Therefore, rollers of different materials can be processed with femtosecond laser.

2. Parameter setting:

- Laser parameters (e.g. pulse energy, repetition frequency, scanning speed, etc.) are optimized according to the material and the desired pattern. For example, pulse energy and scanning speed can be adjusted to control the depth and quality of the etch.

3. Pattern design:

- CAD software is used to design the pattern and structure to be etched, which is converted into laser path data for precise processing by the laser control system.

4. Etching process:

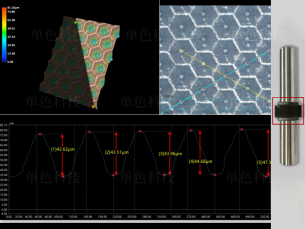

- The roller is mounted on a precision motion platform and laser etched according to the designed pattern and set parameters. The high precision motion system of the femtosecond laser ensures accurate reproduction of the pattern.

Typical applications

1. Printing rollers:

- Fine patterns and textures are etched on printing rollers to improve printing quality and efficiency. For example, microstructures in gravure printing can significantly improve printing accuracy. 2.

2. textile rollers:

- Femtosecond laser can etch complex patterns and structures on textile rollers to improve the diversity and aesthetics of textiles, such as etching different patterns on the embossing rollers.

3. Rolls:

- Microstructure etching on metal rolls to improve the surface properties of the material. Typical applications include the rolling process to increase friction, reduce material slippage, improve processing quality. 4.

4. packaging rolls:

- Used in the packaging industry for fine etching of rollers to produce high quality packaging materials, such as microstructure etching on flexible packaging materials to improve the functionality and visual effect of packaging materials.

Four, monochrome technology femtosecond laser etching equipment processing advantages

1. High precision processing:

- Femtosecond laser can achieve nanometer precision, suitable for making complex and tiny patterns and structures, greatly improving the processing quality.

2. No thermal effect:

- Ultra-short pulse time makes the processing almost no heat-affected zone, avoiding thermal damage and deformation of the material, ensuring the material properties and stability after processing.

3. Multi-material adaptability:

- Femtosecond laser can process a variety of materials, whether metal, ceramics or polymers, can be adjusted to achieve high-quality etching laser parameters.

4. Efficient and environmentally friendly:

- Laser processing does not require chemical reagents, reducing environmental pollution. At the same time, the high efficiency of femtosecond laser processing capability significantly shorten the processing time, improve productivity.

5. High surface quality:

- The surface after femtosecond laser etching is usually very smooth, without the need for additional follow-up treatment, reducing the follow-up processing steps and time.

6. Flexibility and controllability:

- By adjusting the laser parameters, different depths, patterns and structures can be etched, greatly improving the flexibility and controllability of processing.

Monochrome Technology femtosecond laser etching technology on rollers has been widely used in several industrial fields for its high precision, high efficiency and high quality. Whether in the printing, textile, rolling or packaging industries, Monochrome Technology femtosecond laser etching technology provides a reliable solution for demanding precision processing.