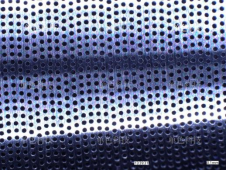

The micropores in the injector pads and injectors play a vital role in a variety of industrial and manufacturing applications. For example:

I. Functions of micropores on fuel injector pads and injectors

1. Control of oil volume:

- The size and number of microholes allow precise control of the amount of oil passing through the injection plate, ensuring a stable and uniform injection process.

- By adjusting the design of the micro-holes, it can meet the demand for oil volume under different working conditions.

2. Improve oil distribution:

- The micro-holes can evenly distribute the oil and prevent the oil from piling up or unevenly coating the oil spraying piece.

- It helps to form a uniform oil film and improve the lubrication effect of the equipment.

3. Improve oiling efficiency:

- The microporous design is optimized to improve the oil spraying efficiency and reduce the waste of oil.

- Improve the overall efficiency of the production line and reduce operating costs.

4. Enhance equipment performance:

- Precise microporous design can optimize the performance of the injector blade, enhance the reliability and life of the equipment.

- Reduces friction and wear, reducing the frequency of equipment maintenance and replacement.

III. Application examples

1. Fuel injection system for automobile engines:

- Microporous ensures fine atomization of fuel, improves combustion efficiency and power output, and reduces emissions.

- Optimize the design of fuel injectors to improve engine performance and economy.

2. Industrial lubrication systems:

- Microporous control of lubricant injection volume and distribution, reducing friction and extending the service life of mechanical equipment.

- Improve the stability and efficiency of production lines.

3. Medical equipment:

- In some medical devices, micropores are used to precisely control the injection of medication or other fluids to ensure accurate dosage and therapeutic effect.

4. aerospace:

- Microporous technology is used to inject fuels and lubricants to improve the performance and reliability of aircraft engines.

- Optimizing combustion and lubrication systems improves overall flight safety and efficiency.

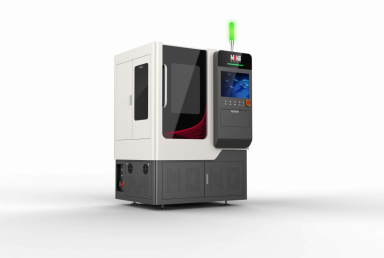

The Monochrome Technology femtosecond laser offers many unique advantages for micro-perforating fuel injection pads and injectors. Femtosecond laser technology is an ultrafast laser processing technology that utilizes laser pulses of extremely short duration (femtoseconds, 1 femtosecond = 10^-15 seconds) for material processing. Due to its extremely short pulse duration, femtosecond lasers produce a very small heat affected zone (HAZ) during material removal and are therefore widely used for high precision and microfabrication.

Fourth, monochrome technology femtosecond laser microporous processing equipment is mainly manifested in the following advantages:

1. High precision and high resolution: femtosecond laser can realize sub-micron processing precision, which can make very fine micro-holes on the oil injection sheet and injector. This is critical for controlling the amount of oil injected and the precision of the injection.

2. Low heat affected zone (HAZ): Due to the ultra-short pulse time of femtosecond laser, there is almost no time for heat conduction after the energy is absorbed by the material, so there is almost no heat-affected zone in the processing area, which reduces the thermal stress and thermal deformation.

3. High material adaptability: Femtosecond laser is capable of processing a wide range of materials, including metals, ceramics, glass and polymers, etc., and is suitable for all types of injector blades and injectors.

4. No thermal damage: the cold processing characteristics of femtosecond laser can avoid thermal damage and retain the original characteristics of the material, which is especially suitable for the processing of heat-sensitive materials.

5. High efficiency and speed: The high energy density of the femtosecond laser makes the material removal speed fast, which is suitable for the rapid microporous processing needs in mass production.

Monochrome Technology's femtosecond laser microporous processing equipment has significant advantages in microporous processing on fuel injector sheets and injectors, and can significantly improve processing accuracy, efficiency and quality. This technology not only meets the current needs of high-performance injection systems, but also promotes the development of related fields in the future.