Femtosecond laser equipment has a variety of advantages in micro-hole drilling, compared with other processing methods, it is outstanding in processing precision, effect, applicable materials and other aspects. The advantages of femtosecond laser equipment are that it can achieve higher processing precision and better processing effect, and at the same time, it is applicable to a wide range of materials and the processing process can be controlled.

The following are some of the advantages of femtosecond laser equipment in micro-hole drilling:

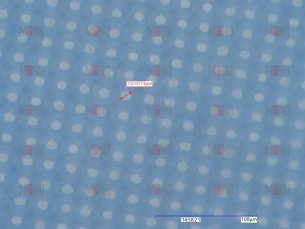

1. High processing precision: femtosecond laser equipment can achieve very high processing precision, can reach the nanometer level precision in microporous processing, so as to meet the demand for high-precision microporous processing.

2. Good processing effect: the microporous holes processed by femtosecond laser equipment have no remelting layer and burr, and can obtain clearer sharp edges and better surface quality, thus prolonging the life of the nozzle.

3. Wide range of processing materials: femtosecond laser equipment can process a variety of materials, including metals, ceramics, glass, polymers, etc., so it is suitable for a wide range of micro-hole processing application scenarios.

4. Fast processing speed: the processing speed of femtosecond laser equipment is very fast, which can greatly improve the efficiency of microporous processing, thus meeting the needs of large-scale microporous processing.

5. Controllable processing: The processing process of femtosecond laser equipment can be precisely controlled by computer, thus realising high-precision and high-efficiency micro-hole processing.

6. Small heat-affected zone: Since the pulse width of femtosecond laser is extremely short, the interaction time with the material is very short, so the heat-affected zone in the processing is very small, and thermal damage to the material can be avoided.

7. Complex shape processing can be achieved: femtosecond laser equipment can be used to realise the processing of complex shapes of micro-holes, such as conical holes, shaped holes, etc., by controlling the path and intensity of the laser beam.

Femtosecond laser equipment has the advantages of high processing precision, good effect and wide range of applicable materials in micro-hole drilling, which makes it the best choice for micro-hole precision drilling. It not only improves the production efficiency, but also ensures the high quality and consistency of the products, which meets the high precision requirements for micro-hole punching in many industries.