In today's era of rapid development of science and technology, the chip as the core component of electronic equipment, its manufacturing process and performance requirements are increasingly stringent. Femtosecond laser processing technology, with its unique advantages, plays an increasingly important role in the field of chip marking.

Femtosecond laser is a kind of laser with extremely short pulse duration, usually on the order of femtosecond (1 femtosecond equals 10^-15 seconds). This extremely short pulse characteristic makes femtosecond laser have very high peak power and instantaneous energy release capability.

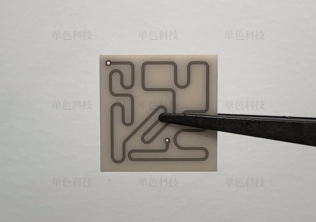

In chip marking, femtosecond laser processing technology shows a number of significant advantages. The first is high precision and resolution. Femtosecond laser can be focused to a very small spot size, to achieve micron-level processing accuracy, so as to inscribe extremely fine lines and patterns on the chip surface. This is of great significance for marking tiny features on the chip, such as the fine lines of integrated circuits and the marking of tiny components.

The heat-affected zone of femtosecond laser processing is extremely small. Due to the extremely short pulse time, the heat does not have time to diffuse, thus greatly reducing the thermal damage to the surrounding material. This is crucial for heat-sensitive materials such as chips, which can effectively avoid the performance degradation or damage of chips caused by thermal effects.

Femtosecond laser can achieve a variety of complex forms of marking. It can not only carry out simple text, digital and graphic marking, but also be able to complete the three-dimensional stereoscopic marking, for the chip to provide more dimensional identification and information storage.

For example, in the production process of chips, each chip needs to be marked with W-one, such as serial number, batch number and so on. Femtosecond lasers can accurately engrave this information on the chip surface, and the marking is clear, long-lasting, and not easy to wear and tamper with. This is of great value for chip quality tracing, anti-counterfeiting and supply chain management.

At the same time, femtosecond lasers can also be used to create microstructures on the chip surface to improve the chip's thermal or optical properties. By etching a specific texture or pattern on the chip surface, the surface area can be increased to improve heat dissipation efficiency, or to achieve a specific optical effect to enhance the performance of the chip.

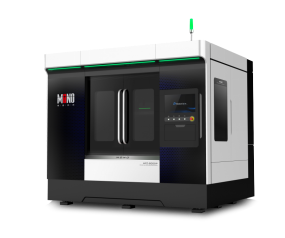

In practice, femtosecond laser processing technology needs to be combined with advanced control systems and inspection equipment to ensure the accuracy and consistency of the marking. At the same time, the operator needs to have professional knowledge and skills to accurately set and adjust the laser parameters to meet the marking requirements of different chips.

With the continuous progress of technology, the application of femtosecond laser processing technology in the field of chip marking is very promising. Femtosecond laser processing technology will bring higher precision, efficiency and innovation to chip manufacturing and promote the sustainable development of the electronics industry.

The application of femtosecond laser processing technology in chip marking is an important breakthrough in modern chip manufacturing process. It not only improves the quality and traceability of chip marking, but also provides a new way for the optimisation and innovation of chip performance, and injects a strong impetus for the development of the electronic information industry.