With the continuous development of modern industry, there is an increasing demand for micro-fine chamfered holes with high depth-to-diameter ratio. These inverted taper holes play an important role in aerospace, automobile manufacturing, electronic equipment and other fields. For example, the inverted taper holes in automotive injector nozzles can improve fuel atomization and combustion efficiency; the air film holes on the blades of aircraft engines help to cool and protect the blades. Traditional processing methods face many difficulties in processing such high-precision, complex-shaped inverted cone holes, and the emergence of femtosecond laser processing technology provides a new way to solve these problems.

First, the principle and characteristics of femtosecond laser processing

Femtosecond laser is a laser with extremely short pulse width (usually on the order of femtoseconds). Its features include: high instantaneous power, which can realize high-precision processing of the material; small heat-affected area, which can effectively reduce the thermal damage in the processing; non-selective to the processing material, which can process a variety of materials.

In the processing of inverted cone hole, femtosecond laser through the instantaneous high energy on the surface of the material, so that it occurs ablation, vaporization and other physical processes, so as to achieve the processing of micro-hole.

Second, femtosecond laser processing inverted cone hole application areas

(A) automobile fuel injector manufacturing

In the manufacture of automobile injector nozzle, the shape and precision of the inverted cone hole has an important impact on the fuel atomization effect and combustion efficiency. Femtosecond laser processing technology can produce high-precision, high-quality inverted cone holes and improve the performance of fuel injectors.

(B) aero-engine blade gas film hole processing

Aero-engine blades work in high temperature gas, the quality of the air film hole is crucial to the cooling protection of the blade. Femtosecond laser processing can avoid the production of recast layer, reduce the damage to the blade, and improve the machining accuracy and surface quality of the gas film hole.

(III) Other fields

In addition to the above fields, femtosecond laser processing of inverted cone hole technology can also be applied to the processing of miniature heat dissipation holes in electronic equipment and the manufacture of fine micro-holes in medical devices.

Advantages and challenges

(I) Advantages

1. High processing precision: it can realize high-precision inverted taper hole processing and meet the strict requirements on the shape and size of the hole.

2. Low thermal impact: effectively reduce thermal damage and maintain the original properties of the material.

3. Wide material adaptability: can process a variety of materials, including metals, ceramics, polymers and so on.

4. No need for subsequent processing: the surface quality of the processed holes is good, usually without additional grinding, polishing and other subsequent processing procedures.

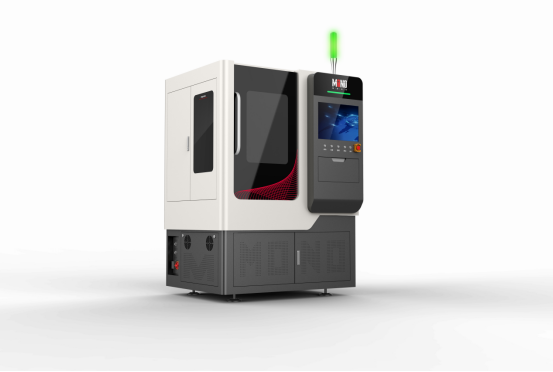

Monochrome Technology Femtosecond Laser Processing of Inverted Cone Hole Technology, as an advanced manufacturing means, has significant advantages and broad application prospects. It has been widely used in more fields through continuous improvement of devices and methods to improve processing efficiency, reduce costs and enhance process stability. In the future, with the further development of technology, femtosecond laser processing is expected to play a greater role in the processing of micro-fine inverted taper holes, providing strong support for the development of high-end manufacturing. Give full play to the advantages of various technologies to realize the processing of more complex and more demanding parts. In addition, the study of real-time monitoring and intelligent control of the machining process will also help to improve machining quality and productivity.

In practical application, it is necessary to select the appropriate femtosecond laser processing methods and parameters according to the specific processing needs and material characteristics, in order to give full play to the advantages of this technology and realize high-quality, high-precision inverted taper hole processing. At the same time, to strengthen the research and development of related technologies and innovation, will promote the continuous development of femtosecond laser processing technology, for industrial production to bring more possibilities and opportunities.