In today's advanced medical technology, CT scanning equipment is undoubtedly one of the most important tools for diagnosing diseases. As the core component of the CT tube, its performance directly affects the quality of the scanning image and the accuracy of the diagnosis. In recent years, the application of femtosecond laser technology has brought new breakthroughs in the treatment of CT tube bearing surfaces.

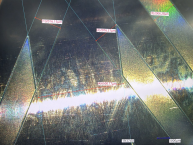

Femtosecond laser, with its extremely short pulse width and high peak power, is able to achieve high-precision and low-damage processing on the material surface. When applied to the surface etching of CT ball bearings, it has shown stunning results. A series of grooves with a width of 2mm, a depth of 20μm and a surface roughness of Ra0.2 were precisely etched on the bearing surface. Behind this seemingly simple geometry lies a complex scientific principle and exquisite technical process.

Firstly, why are these grooves etched into the surface of CT ball bearings? The existence of the grooves can improve the lubrication performance of the bearings. Good lubrication is the key to ensure stable operation and prolonged service life of CT ball tubes during their high-speed operation. These specifically sized grooves store the right amount of lubricant, forming an oil film that reduces friction and wear. At the same time, the precisely controlled dimensions of the grooves ensure the stability and uniformity of the oil film, thus increasing the efficiency and reliability of the bearing.

The high precision of femtosecond laser processing is demonstrated by the requirement of Ra0.2 surface roughness. Such a low surface roughness can reduce the microscopic unevenness of the bearing surface, reduce the coefficient of friction, and further improve the lubrication effect. In addition, the smooth surface can also reduce the adhesion and accumulation of impurities, reducing the risk of bearing wear and ensuring that the CT ball tube always maintains good performance over a long period of time.

The process of femtosecond laser etching is a highly precise operation. The laser beam is focused on the bearing surface in an instant, generating an extremely high energy density that causes the material to evaporate or sublimate instantly, resulting in the formation of grooves. Due to the extremely short pulse duration of the femtosecond laser, the heat-affected area is very small and causes little thermal damage to the surrounding material. This allows the etched bearing surface to maintain good mechanical properties and chemical stability.

In the actual processing, precise control of the laser parameters, such as pulse energy, pulse width, repetition frequency, etc., is required to ensure that the dimensions and shapes of the grooves meet the requirements. At the same time, real-time monitoring and adjustment of the machining process is also required to ensure the stability and consistency of the machining quality. This requires close co-operation between advanced laser processing equipment and professional technicians.

Monochrome Technology femtosecond laser etching of grooves on the surface of CT ball tube bearings not only improves the performance of the bearings, but also brings new opportunities for the development of CT scanning equipment. With the continuous progress of medical technology, the quality and resolution of CT images are required to be higher and higher. And high-performance CT ball tubes are the key to achieve this goal. Optimisation of the bearing surface by femtosecond laser technology can improve the rotational accuracy and stability of the ball tube, thus improving the quality and resolution of the scanned image.

In addition, femtosecond laser processing has the advantages of environmental protection, high efficiency and good repeatability. Compared with traditional mechanical processing methods, it does not require the use of coolant and lubricants, reducing environmental pollution. At the same time, it can complete the processing task quickly and improve productivity. Moreover, due to the high precision and good repeatability of laser processing, it can ensure the stability and consistency of product quality.

In conclusion, the monochromatic technology femtosecond laser for etching a series of grooves of specific size and surface roughness on the bearing surface of CT ball tubes is a technological innovation of great significance. It provides a new way to improve the performance of CT tubes and the quality of CT scanning equipment. It is believed that femtosecond laser technology will play an even more important role in the future medical technology field and make greater contributions to human health.