In the process of rapid development of modern technology, the processing technology of materials has been constantly pushed forward to meet the needs of increasingly complex and demanding applications. Among them, femtosecond laser drilling technology shows unique advantages and great potential in processing silicon carbide materials.

Silicon carbide, as a high-performance engineering material, has a wide range of applications in many fields such as aerospace, electronics, and machinery due to its excellent hardness, high temperature resistance, and corrosion resistance. However, due to its extremely high hardness, traditional machining methods often face many difficulties when drilling holes in silicon carbide, such as severe tool wear and difficult to ensure machining accuracy. The emergence of femtosecond laser drilling technology has brought a new solution to the processing of silicon carbide.

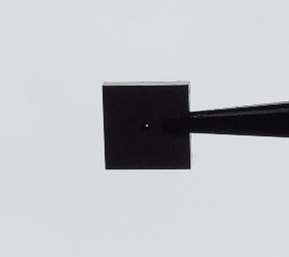

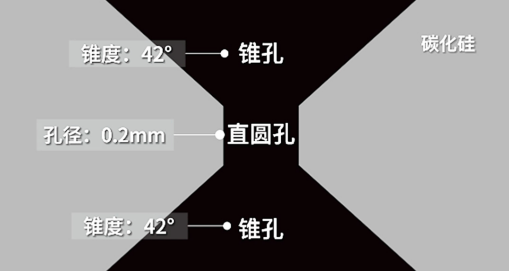

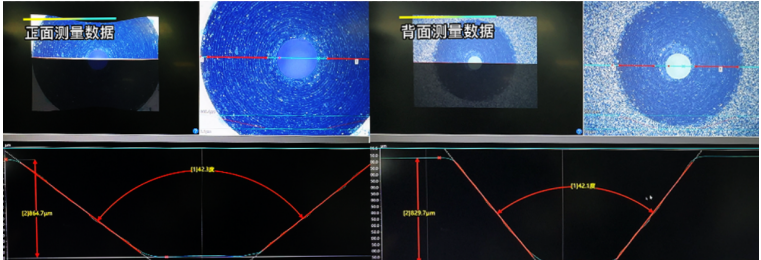

This study is about the femtosecond laser drilling of 2mm-thick silicon carbide, which has a unique hole structure consisting of two conical holes at the top and bottom and a straight circular hole in the middle. The taper of the conical holes is 42° and the diameter of the straight holes is 0.2 mm, which undoubtedly brings great difficulties to the processing.

Firstly, for the machining of the upper and lower tapered holes, controlling the taper to exactly 42° is no easy task. The femtosecond laser concentrates energy in a very small area in a very short pulse time, generating intense photochemical and thermal effects, but ensuring that the laser uniformly removes material at different locations to form a smooth taper requires precise laser scanning path planning and energy distribution control. Deviation at any point may result in inaccurate taper, affecting the structure and performance of the entire hole.

The straight circular hole in the centre has a diameter of only 0.2mm, which is a very small size and requires a very high degree of processing precision. Although the femtosecond laser has high-precision characteristics, to drill such a small straight hole without damaging the surrounding material and at the same time to ensure its perpendicularity and surface quality, it is necessary to carry out extremely fine optimisation of the laser focusing and scanning methods. Moreover, during the process, it is also necessary to ensure that the straight circular holes and the upper and lower conical holes meet naturally and smoothly, which further increases the difficulty of the process.

However, Monochrome Technology perfectly combines tapered holes, straight holes and conical holes, and achieves the precise processing of this complex hole structure by precisely adjusting and optimising parameters such as laser pulse energy, pulse width, repetition frequency and scanning speed. At the same time, in order to ensure the stability and consistency of the processing quality, it also adopts advanced monitoring and feedback system, real-time monitoring of various parameters in the processing process, and timely adjustment of processing parameters according to the feedback information.

In conclusion, the unique structural design of the femtosecond laser drilling of 2mm thick silicon carbide with tapered + straight circular + tapered holes demonstrates the great challenges and strength of Monochrome Technology's femtosecond laser technology in the field of material processing. The continuous development and improvement of this technology will bring more innovations and breakthroughs to various industries.