In the field of modern precision manufacturing, femtosecond lasers are playing a key role in the processing of shaped through-holes by virtue of their unique advantages, and have a wide range of applications from microchip manufacturing in the electronics industry to parts processing in the aerospace field to the production of instruments in the medical field.

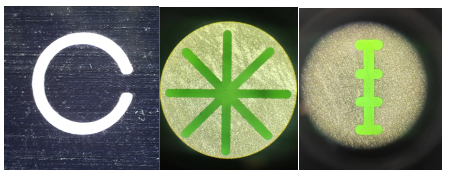

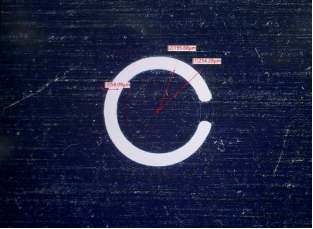

The ultra-short pulse characteristics of femtosecond lasers allow for rapid and precise processing when interacting with materials. This is critical for processing shaped through-holes in 0.5mm thick stainless steel sheets. When machining a C-shaped through-hole with a width of just 58μm, the femtosecond laser first concentrates the energy highly through an advanced focusing system, with a spot that is accurate down to the micron level and ensures that it is applied to a very small machining area. In the process of processing, in order to achieve the front and back without taper, on the one hand, it is necessary to accurately regulate the laser energy, the use of precision energy monitoring and feedback devices to ensure that the laser pulse in the penetration of stainless steel sheet energy stability and uniform distribution. On the other hand, the incident angle of the laser is carefully designed and optimised according to the physical properties of stainless steel, so that the laser beam acts on the material at a Z-optimal angle, thus reducing the uneven force on the hole wall, and ensuring that the through-hole wall is smooth and vertical. The professional software system developed by Monochrome Technology can accurately simulate and analyse these parameters of the laser, providing a reliable basis for the setting of processing parameters in advance, which greatly improves the processing quality.

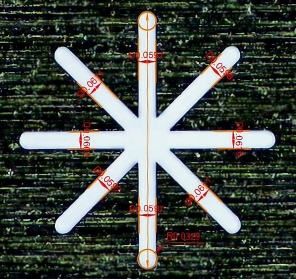

Due to its complex structure, the femtosecond laser's numerical control system plays a key role in the processing of the 60 μm metre shaped through-hole. The system is able to precisely plan the scanning path of the laser and switch precisely at the intersection of different lines and corners. In special positions such as corners, the laser energy and pulse frequency are adjusted by advanced pulse modulation technology according to the demand of material removal to ensure the accuracy and stability of processing. Meanwhile, in order to safeguard the overall accuracy of the metre-shaped through-hole, the online monitoring system monitors the processing in real time and provides immediate feedback and adjustment of laser parameters or processing paths once deviations in line width and shape are detected. Monochrome Technology's monitoring equipment and data analysis algorithms can quickly and accurately identify these deviations and provide optimisation solutions to ensure smooth processing.

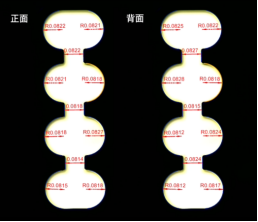

For a shaped through hole with a radius of 0.82, it is important to ensure that the shape of the hole is regular and the dimensions are precise. The precise positioning of the laser beam during machining is ensured by optimising the co-working mechanism of the laser focusing system and the CNC positioning system. During the machining process, the laser-material interaction is precisely controlled according to the preset radius parameters. At the same time, considering the special shape requirements of the shaped holes, a special processing algorithm is used to enable the laser to process in accordance with the predetermined trajectory, ensuring the smoothness of the inner wall of the holes as well as the consistency of the overall shape. This kind of shaped through-hole has a unique value in the field of optical devices, precision machinery and other fields. For example, it can be used as a special through-hole or lens fixing structure in the manufacture of optical devices, and in the field of precision machinery, it can provide a key structural foundation for micro transmission or fluid control components. Monochrome Technology is actively exploring in the relevant fields, and its development of high-precision positioning accessories and advanced algorithm optimisation solutions contribute to the further enhancement of the precision of shaped through-hole machining.

Femtosecond lasers have a significant track record in shaped through-hole processing. In the field of electronics, it provides support for chip manufacturing; in aerospace, it helps parts processing; and in medical treatment, it facilitates the production of instruments. With the development of technology and monochrome technology in technology research and development, equipment manufacturing, software support and other aspects of assistance, femtosecond laser processing of shaped through-hole will promote the upgrading of related industries, continue to shine in the field of manufacturing, to bring us more high-quality products and components.