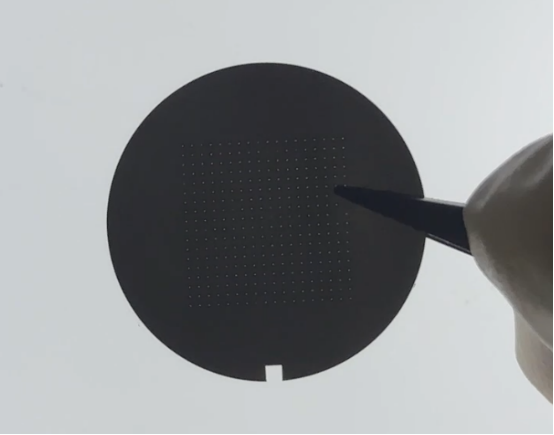

In the field of modern materials processing, femtosecond laser technology occupies an important position in high-precision processing by virtue of its unique advantages. For example, in the processing of micro-hole arrays on 0.2mm thick stainless steel sheets, the goal is to create micro-holes with a diameter of 30μm, no taper on the front and back, an accuracy of ±1μm and a high degree of roundness.

Stainless steel sheets are widely used in many industries such as electronics, medical, and machinery manufacturing due to their good strength and corrosion resistance. However, it is not easy to process micro-hole arrays on 0.2mm thick stainless steel sheets to meet specific requirements. Traditional processing methods, such as mechanical drilling, are prone to breakage of the drill bit and difficult to ensure the accuracy and roundness of the holes when processing such small diameters. At the same time, the large stress generated by traditional processing tends to deform the stainless steel sheet, which makes it impossible to achieve the requirement of taper-free front and back sides.

Monochrome Technology's femtosecond laser processing principle is to use a very short pulse time, instantaneous release of high energy. When the laser acts on the stainless steel sheet, the material absorbs the laser energy and is instantly ionised into a plasma state, followed by gasification and evaporation to achieve material removal. For the processing of 30μm aperture microvias, Monochrome's femtosecond laser system is able to accurately locate the microvias through the precise optical control and the coordinated operation of the motion platform. During processing, the stable output of pulse energy is critical. If the energy fluctuates too much, it will lead to inconsistent hole size. By precisely regulating the energy of the laser pulse, it is possible to ensure that the diameter of each microvia is close to 30μm and that the accuracy is controlled within the range of ±1μm.

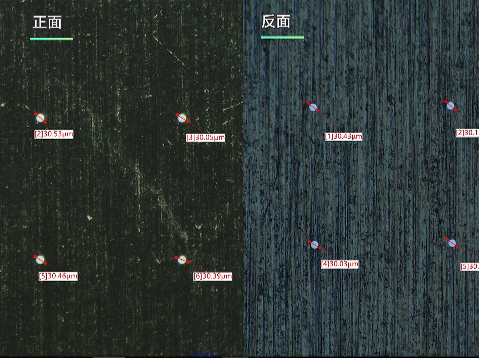

In order to achieve taper-free front and back surfaces, the ultra-short pulse characteristics of the Monochromatic Technology femtosecond laser play an important role. Because the pulse duration is so short, the heat does not have time to spread to the surrounding material, thus effectively avoiding material deformation and taper due to heat conduction. At the same time, the depth of focus of the laser is precisely set, resulting in uniform processing in the thickness direction of the stainless steel sheet.

The high degree of roundness is achieved thanks to the high quality beam of the monochromatic femtosecond laser. The laser beam has a uniform energy distribution after focusing, and when applied to the stainless steel material, it removes the material uniformly, resulting in smooth hole walls and consistent removal at all points around the circumference. True roundness can be further improved by optimising laser processing parameters such as pulse frequency and scanning speed.

Such microvia arrays have important applications in the electronics industry. For example, in mobile phone circuit boards, microvia arrays can achieve the connection between high-density lines and improve the integration of circuit boards. In the field of medical devices, such as the manufacture of microfluidic chips, high-precision microvia arrays can accurately control the flow and reaction of liquids and improve the accuracy of detection. In aerospace component manufacturing, microvia arrays help reduce component weight while maintaining structural strength and improving fuel efficiency. Monochrome Technology's femtosecond laser technology is continuously contributing to the development of various industries, driving modern material processing to a new level of higher precision and efficiency.